Wholesale Discount N08825 Chemical Injection Tubing - Incoloy 825 Chemical Injection Line Tube – MEILONG

Wholesale Discount N08825 Chemical Injection Tubing - Incoloy 825 Chemical Injection Line Tube – MEILONG Detail:

Alloy Materials

| Austenitic: | 316L | ASTM A-269 |

| Duplex: | S31803/S32205 | ASTM A-789 |

| S32750 | ASTM A-789 | |

| Nickel alloy: | N08825 | ASTM B-704; ASTM B-423 |

| N06625 | ASTM B-704; ASTM B-444 | |

| CuNi alloy | Monel 400 | ASTM B-730; ASTM B-165 |

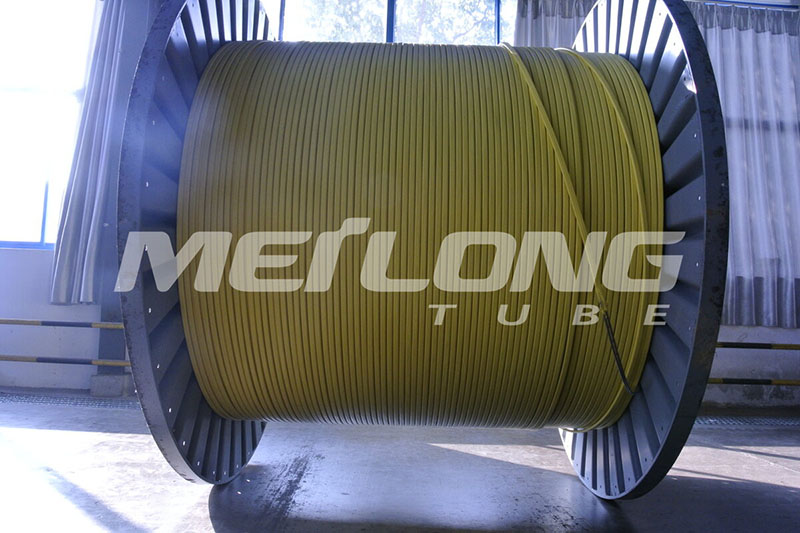

Product Display

Alloy Feature

Characteristics

Excellent resistance to reducing and oxidizing acids.

Good resistance to stress-corrosion cracking.

Satisfactory resistance to localized attack like pitting and crevice corrosion.

Very resistant to sulfuric and phosphoric acids.

Good mechanical properties at both room and elevated temperatures up to approximately 1020° F.

Permission for pressure-vessel use at wall temperatures up to 800°F.

Application

Chemical Processing.

Pollution-control.

Oil and gas well piping.

Nuclear fuel reprocessing.

Components in pickling equipment like heating coils, tanks, baskets and chains.

Acid production.

Tubing Features

Close dimensional tolerances.

Considerably enhanced mechanical properties.

Superior surface finish.

High cleanness of inside surface.

Controlled ovality, eccentricity.

Chemical Composition

|

Nickel |

Chromium |

Iron |

Molybdenum |

Carbon |

Manganese |

Silicon |

Sulfur |

Aluminum |

Titanium |

Copper |

|

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

|

|

|

min. |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

38.0-46.0 |

19.5-23.5 |

22.0 |

2.5-3.5 |

0.05 |

1.0 |

0.5 |

0.03 |

0.2 |

0.6-1.2 |

1.5-3.0 |

| Norm Equivalence | |||

|

Grade |

UNS No |

Euro norm |

|

|

No |

Name |

||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 |

| 825 | N08825 | 2.4858 | NiCr21Mo |

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Wholesale Discount N08825 Chemical Injection Tubing - Incoloy 825 Chemical Injection Line Tube – MEILONG , The product will supply to all over the world, such as: Bolivia, Latvia, Chile, Ought to any of these products be of curiosity to you, remember to allow us to know. We are going to be satisfied to give you a quotation on receipt of one's in depth specs. We've our private experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!