Wholesale Dealers of Super Duplex 2507 Chemical Injection Line - Inconel 625 Chemical Injection Line Tube – MEILONG

Wholesale Dealers of Super Duplex 2507 Chemical Injection Line - Inconel 625 Chemical Injection Line Tube – MEILONG Detail:

Application

In all fields of the oil and gas industry, chemicals are injected into process lines and fluids. Take oilfield services, chemicals are used to film the side of the wellbore for improved stability. In pipelines they avoid build-up and keep the infrastructure healthy.

Other application:

In the oil and gas industry we inject chemicals in order.

To protect the infrastructure.

To optimize processes.

To assure flow.

And to improve productivity.

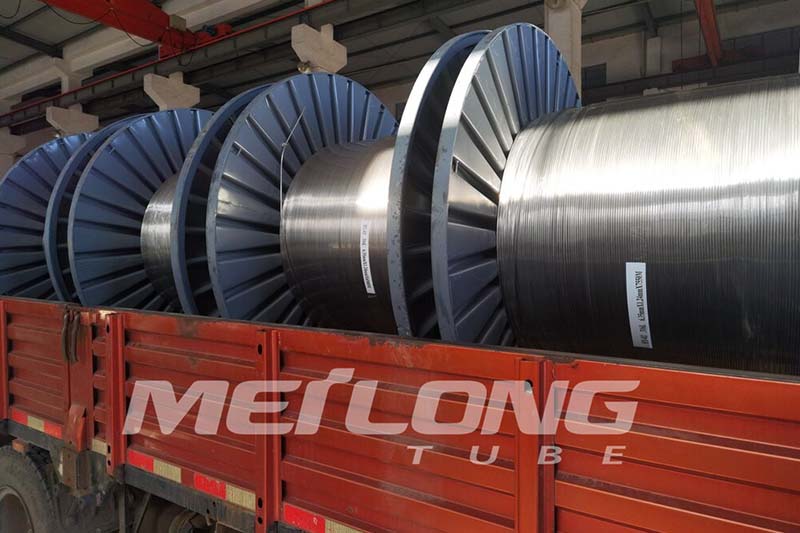

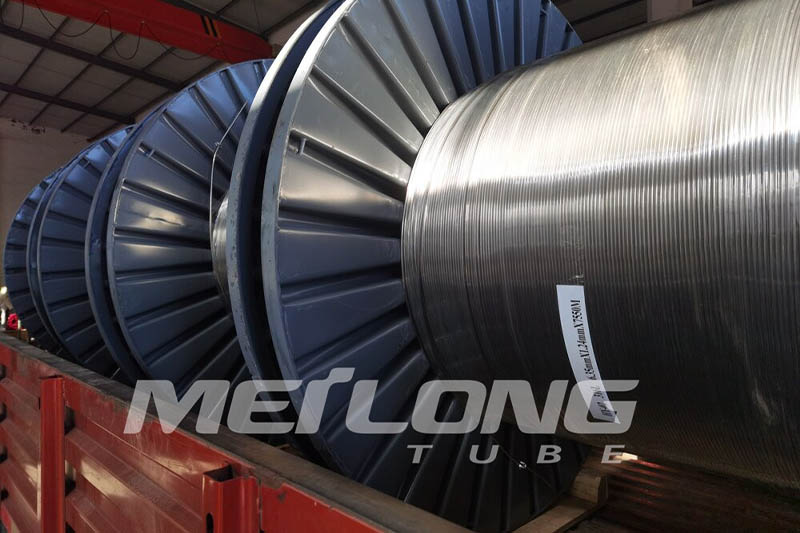

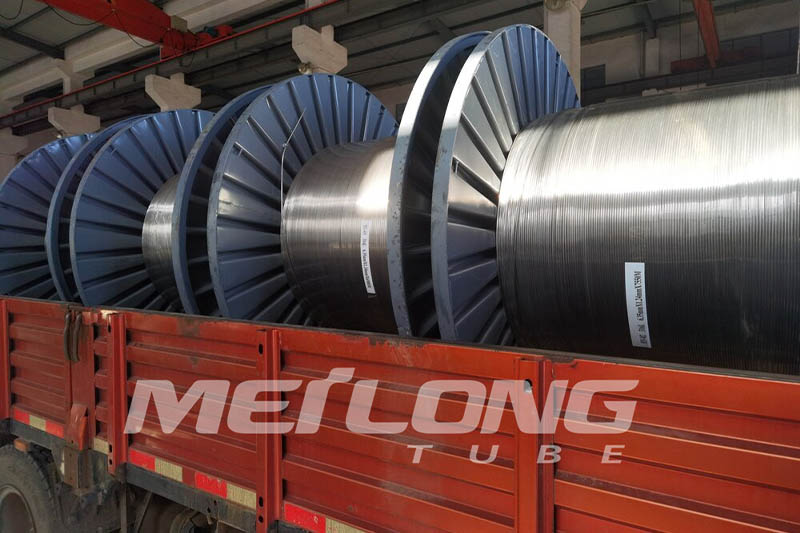

Product Display

Alloy Feature

Inconel 625 is a material with excellent resistance to pitting, crevice and corrosion cracking. Highly resistant in a wide range of organic and mineral acids. Good high temperature strength.

Characteristics

Excellent mechanical properties at both extremely low and extremely high temperatures.

Outstanding resistance to pitting, crevice corrosion and intercrystalline corrosion.

Almost complete freedom from chloride induced stress corrosion cracking.

High resistance to oxidation at elevated temperatures up to 1050C.

Good resistance to acids, such as nitric, phosphoric, sulfuric and hydrochloric, as well as to alkalis makes possible the construction of thin structural parts of high heat transfer.

Chemical Composition

|

Nickel |

Chromium |

Iron |

Molybdenum |

Columbium + Tantalum |

Carbon |

Manganese |

Silicon |

Phosphorus |

Sulfur |

Aluminum |

Titanium |

Cobalt |

|

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

|

min. |

|

max. |

|

|

max. |

max. |

max. |

max. |

max. |

max. |

max. |

max. |

|

58.0 |

20.0-23.0 |

5.0 |

8.0-10.0 |

3.15-4.15 |

0.10 |

0.50 |

0.5 |

0.015 |

0.015 |

0.4 |

0.40 |

1.0 |

|

Norm Equivalence |

|||

|

Grade |

UNS No |

Euro norm |

|

|

No |

Name |

||

|

Alloy |

ASTM/ASME |

EN10216-5 |

EN10216-5 |

|

625 |

N06625 |

2.4856 |

NiCr22Mo9Nb |

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation first, customer first" for Wholesale Dealers of Super Duplex 2507 Chemical Injection Line - Inconel 625 Chemical Injection Line Tube – MEILONG , The product will supply to all over the world, such as: Muscat, Norway, Greece, Now we are sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We are ready to share win-win corporation.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!