Special Price for S32750 Capillary Tubing Control Line - Super Duplex 2507 Control Line Flatpack – MEILONG

Special Price for S32750 Capillary Tubing Control Line - Super Duplex 2507 Control Line Flatpack – MEILONG Detail:

Product Introduction

A small-diameter hydraulic line used to operate downhole completion equipment such as the surface controlled subsurface safety valve (SCSSV). Most systems operated by control line operate on a fail-safe basis. In this mode, the control line remains pressurized at all times. Any leak or failure results in loss of control line pressure, acting to close the safety valve and render the well safe.

Alloy Feature

Duplex 2507 is a super duplex stainless steel designed for applications which demand exceptional strength and corrosion resistance. Alloy 2507 has 25% chromium, 4% molybdenum, and 7% nickel. This high molybdenum, chromium and nitrogen content results in excellent resistance to chloride pitting and crevice corrosion attack and the duplex structure provides 2507 with exceptional resistance to chloride stress corrosion cracking.

Usage of Duplex 2507 should be limited to applications below 600° F (316° C). Extended elevated temperature exposure can reduce both the toughness and corrosion resistance of alloy 2507.

Duplex 2507 possesses excellent mechanical properties. Often a light gauge of 2507 material can be used to achieve the same design strength of a thicker nickel alloy. The resulting savings in weight can dramatically reduce the overall cost of fabrication.

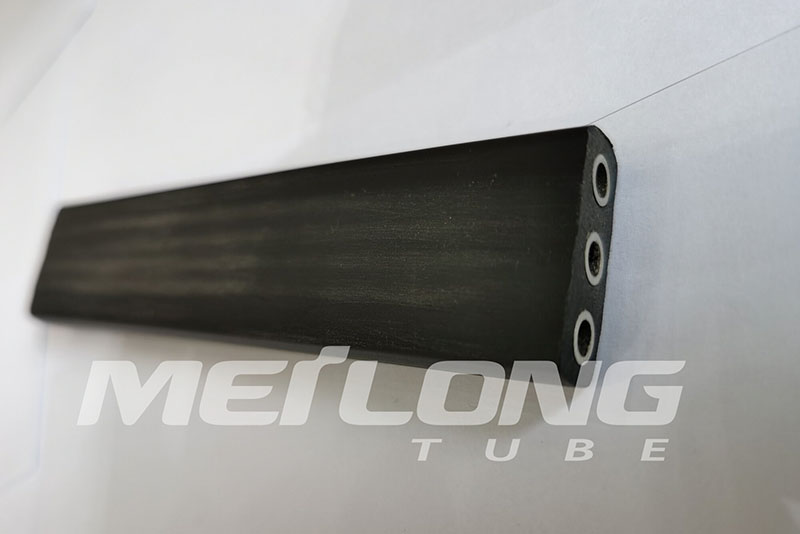

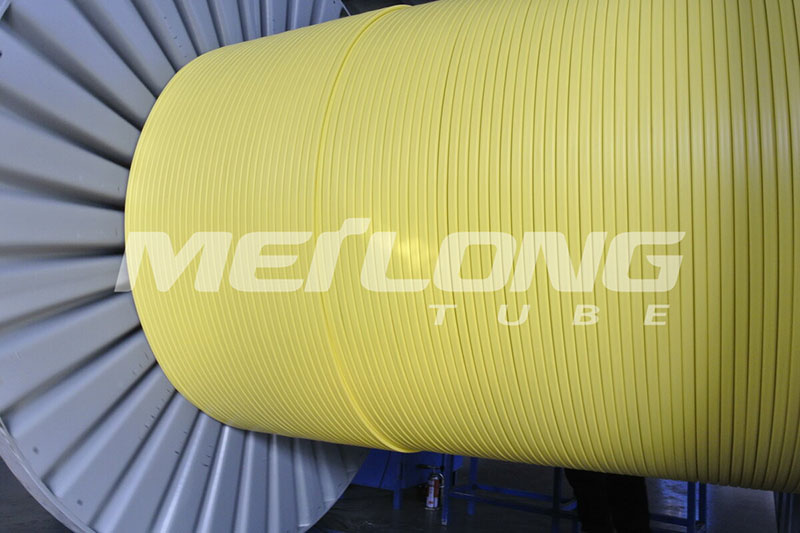

Product Display

Application

Encapsulation is a plastic that is extruded over metal tube. Encapsulation prevents damage to the metal tubes during the manufacturing process. The encapsulation also provides additional abrasion resistance and is required if cable protectors are installed to enhance the holding force over each production tubing connection.

Encapsulations are available in a wide range of configurations with options of single pass encapsulation and dual pass encapsulation for added protection.

Product detail pictures:

Related Product Guide:

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for Special Price for S32750 Capillary Tubing Control Line - Super Duplex 2507 Control Line Flatpack – MEILONG , The product will supply to all over the world, such as: Manila, Islamabad, Paraguay, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.