Santoprene TPV Encapsulated Incoloy 825 Control Line Tubing – MEILONG

Santoprene TPV Encapsulated Incoloy 825 Control Line Tubing – MEILONG Detail:

Product Introduction

Each one tubing coil is a completely continuous length without orbital welds.

Each one tubing coil is hydrostatic tested with a targeted pressure.

The test can be witnessed on site by the third party inspectors (SGS, BV, DNV).

Other tests are eddy current test, chemicals, flattening, flaring, tensile, yield, elongation, hardness for the material quality.

Meilong Tube offers coiled tubing in a wide range of corrosion resistant stainless steels, nickel alloys. We have extensive experience in product supply and innovation in this sector, from the technological advances required for subsea developments in the 1999 to the deepwater challenges of today.

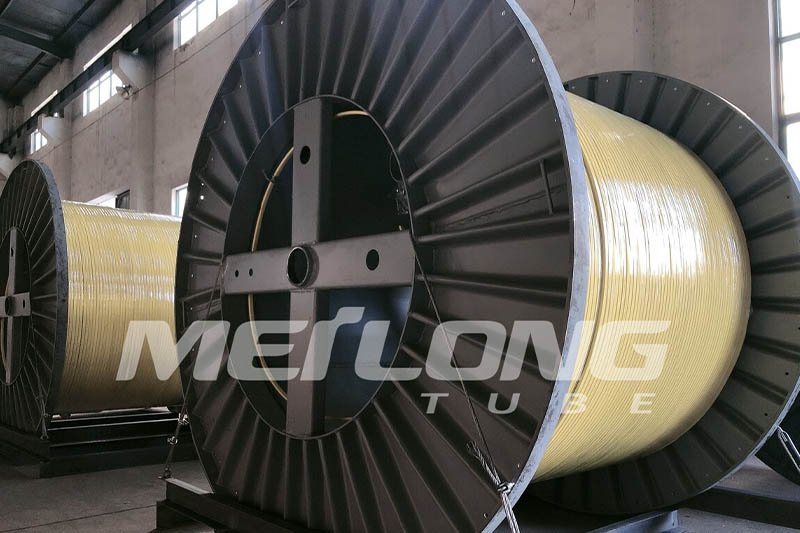

Product Display

Alloy Feature

Application

Chemical Processing.

Pollution-control.

Oil and gas well piping.

Nuclear fuel reprocessing.

Components in pickling equipment like heating coils, tanks, baskets and chains.

Acid production.

Dimensional Tolerance

| ASTM B704 / ASME SB704, Incoloy 825, UNS N08825, Inconel 625, UNS N06625 | ||

| ASTM B751 / ASME SB751 | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) | ±0.004’’ (±0.10 mm) | ±12.5% |

| 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) | ±0.0075’’ (±0.19 mm) | ±12.5% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) | ±0.004’’ (±0.10 mm) | ±10% |

| 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) | ±0.004’’ (±0.10 mm) | ±8% |

| ASTM B423 / ASME SB423, Incoloy 825, UNS N08825 | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’≤OD<3/16’’ (3.18≤OD<4.76 mm) | +0.003’’ (+0.08 mm) / -0 | ±10% |

| 3/16≤OD<1/2’’ (4.76≤OD<12.7 mm) | +0.004’’ (+0.10 mm) / -0 | ±10% |

| 1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm) | +0.005’’ (+0.13 mm) / -0 | ±10% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’ ≤OD<3/16’’ (3.18≤OD<4.76 mm) | +0.003’’ (+0.08 mm) / -0 | ±10% |

| 3/16≤OD<1/2’’ (4.76≤OD<12.7 mm) | +0.004’’ (+0.10 mm) / -0 | ±10% |

| 1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm) | +0.004’’ (+0.10 mm) / -0 | ±8% |

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for Santoprene TPV Encapsulated Incoloy 825 Control Line Tubing – MEILONG , The product will supply to all over the world, such as: London, Greece, Jeddah, With the best technological support, we have tailored our website for the best user experience and kept in mind your ease of shopping. we ensure that the best reaches you at your doorstep, in the shortest possible time and with the help of our efficient logistical partners i.e DHL and UPS. We promise quality, living by the motto of promising only what we can deliver.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.