Santoprene TPV Encapsulated Incoloy 825 Control Line Tube – MEILONG

Santoprene TPV Encapsulated Incoloy 825 Control Line Tube – MEILONG Detail:

Product Introduction

A small-diameter hydraulic line used to operate downhole completion equipment such as the surface controlled subsurface safety valve (SCSSV). Most systems operated by control line operate on a fail-safe basis. In this mode, the control line remains pressurized at all times. Any leak or failure results in loss of control line pressure, acting to close the safety valve and render the well safe.

The tubing products for the oil & gas sector have been successfully applied in some of the most aggressive subsea and downhole conditions and we have a long proven track record of supplying products that meet the strict quality requirements of the oil and gas sector.

Meilong Tube offers coiled tubing in a wide range of corrosion resistant stainless steels, nickel alloys. We have extensive experience in product supply and innovation in this sector, from the technological advances required for subsea developments in the 1999 to the deepwater challenges of today

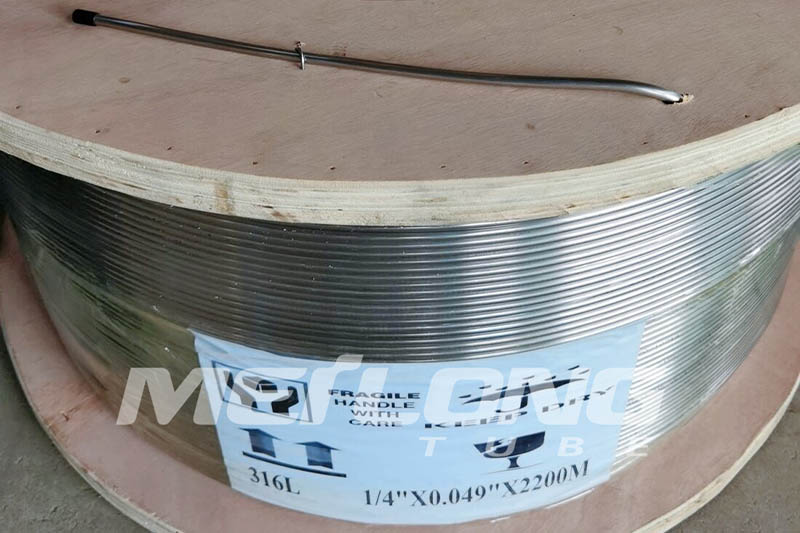

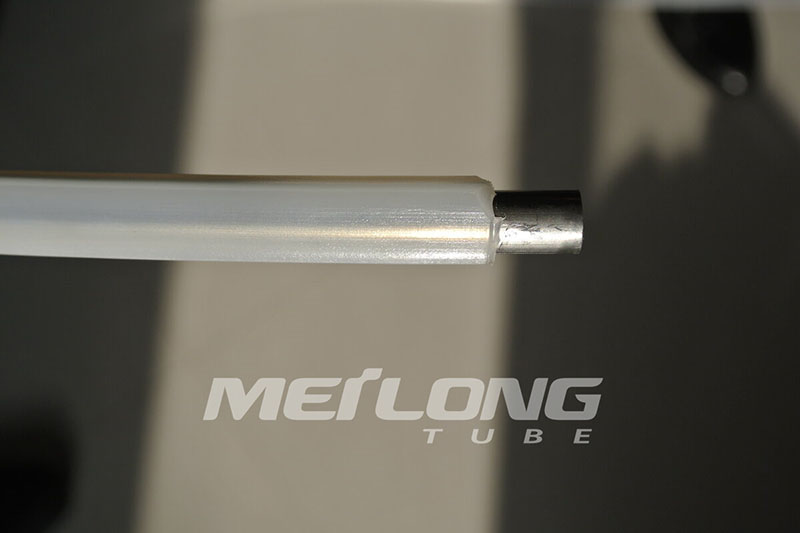

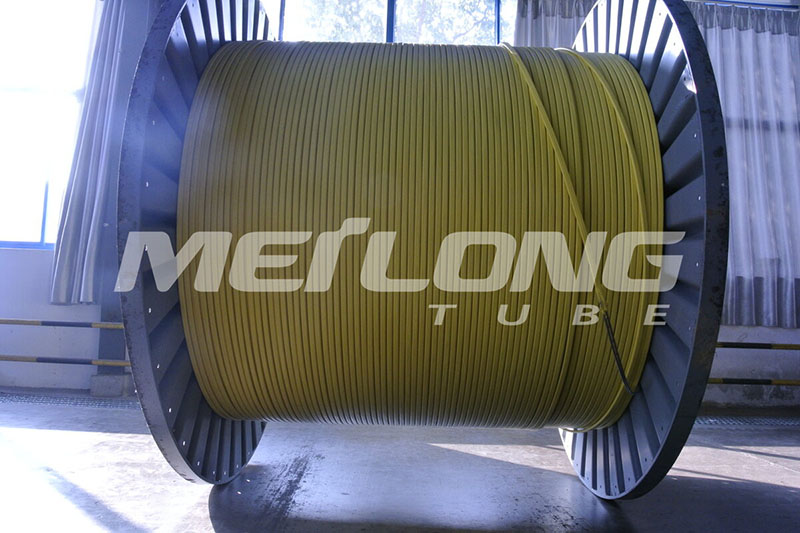

Product Display

Alloy Feature

Incoloy alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum and copper. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Chemical Composition

|

Incoloy 825 |

||||||||||

|

Nickel |

Chromium |

Iron |

Molybdenum |

Carbon |

Manganese |

Silicon |

Sulfur |

Aluminum |

Titanium |

Copper |

|

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

|

|

|

min. |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

38.0-46.0 |

19.5-23.5 |

22.0 |

2.5-3.5 |

0.05 |

1.0 |

0.5 |

0.03 |

0.2 |

0.6-1.2 |

1.5-3.0 |

|

Norm Equivalence |

|||

|

Grade |

UNS No |

Euro norm |

|

|

No |

Name |

||

|

Alloy |

ASTM/ASME |

EN10216-5 |

EN10216-5 |

|

825 |

N08825 |

2.4858 |

NiCr21Mo |

Product detail pictures:

Related Product Guide:

Responsible excellent and fantastic credit rating standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, buyer supreme" for Santoprene TPV Encapsulated Incoloy 825 Control Line Tube – MEILONG , The product will supply to all over the world, such as: Cancun, Romania, US, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.