Reasonable price Stainless Steel Capillary Tubing - Santoprene TPV Encapsulated 316L Chemical Injection Line – MEILONG

Reasonable price Stainless Steel Capillary Tubing - Santoprene TPV Encapsulated 316L Chemical Injection Line – MEILONG Detail:

Typical Tubing Size

|

Imperial size |

Metric size |

||

|

OD inch |

WT inch |

OD mm |

WT mm |

|

1/8 (0.125) |

0.028 |

3.18 |

0.71 |

|

0.035 |

3.18 |

0.89 |

|

|

3/16 (0.188) |

0.028 |

4.76 |

0.71 |

|

0.035 |

4.76 |

0.89 |

|

|

0.049 |

4.76 |

1.24 |

|

|

1/4 (0.250) |

0.035 |

6.35 |

0.89 |

|

0.049 |

6.35 |

1.24 |

|

|

0.065 |

6.35 |

1.65 |

|

|

0.083 |

6.35 |

2.11 |

|

|

3/8 (0.375) |

0.035 |

9.53 |

0.89 |

|

0.049 |

9.53 |

1.24 |

|

|

0.065 |

9.53 |

1.65 |

|

|

0.083 |

9.53 |

2.11 |

|

|

1/2 (0.500) |

0.035 |

12.7 |

0.89 |

|

0.049 |

12.7 |

1.24 |

|

|

0.065 |

12.7 |

1.65 |

|

|

0.083 |

12.7 |

2.11 |

|

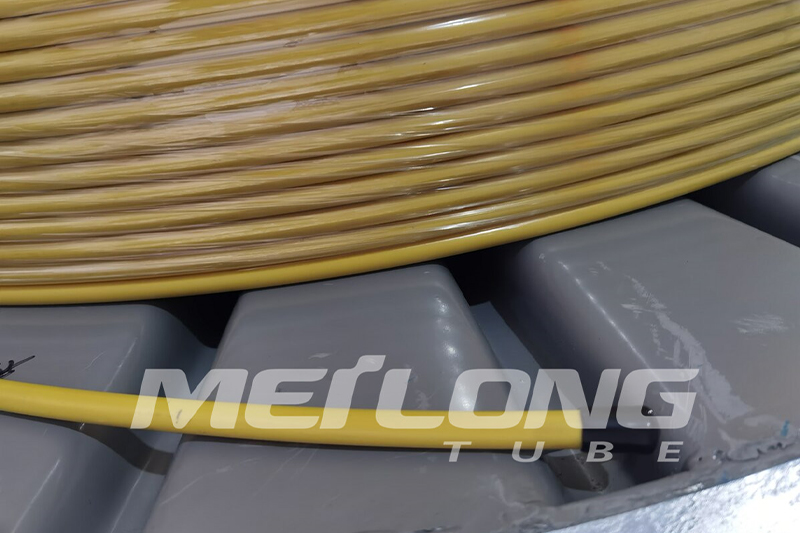

Product Display

Alloy Feature

Caustic Environments

Austenitic steels are susceptible to stress corrosion cracking. This may occur at temperatures above about 60°C (140°F) if the steel is subjected to tensile stresses and at the same time comes into contact with certain solutions, particularly those containing chlorides. Such service conditions should therefore be avoided. Conditions when plants are shut down must also be considered, as the condensates which are then formed can develop conditions that lead to both stress corrosion cracking and pitting.

SS316L has a low carbon content and therefore better resistance to intergranular corrosion than steels of type SS316.

Encapsulation Features

Maximize protection of downhole line

Increase crush resistance during installation

Protect injection line against abrasion and pinching

Eliminate long term stress corrosion failure of control line

Improve clamping profile

Single or multiple encapsulation for ease of running and added protection

Technical Datasheet

|

Alloy |

O.D. |

W.T. |

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Working Pressure |

Burst Pressure |

Collapse Pressure |

|

inch |

inch |

Mpa |

Mpa |

% |

HV |

psi |

psi |

psi |

|

|

|

|

min. |

min. |

min. |

max. |

min. |

min. |

min. |

|

|

SS316L |

0.375 |

0.035 |

172 |

483 |

35 |

190 |

3,818 |

17,161 |

5,082 |

|

SS316L |

0.375 |

0.049 |

172 |

483 |

35 |

190 |

5,483 |

24,628 |

6,787 |

|

SS316L |

0.375 |

0.065 |

172 |

483 |

35 |

190 |

7,517 |

33,764 |

8,580 |

|

SS316L |

0.375 |

0.083 |

172 |

483 |

35 |

190 |

9,749 |

43,777 |

10,357 |

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of Reasonable price Stainless Steel Capillary Tubing - Santoprene TPV Encapsulated 316L Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Bangkok, Haiti, Switzerland, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing products, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.