Reasonable price Stainless Steel Capillary Tubing - Encapsulated Incoloy 825 Chemical Injection Line – MEILONG

Reasonable price Stainless Steel Capillary Tubing - Encapsulated Incoloy 825 Chemical Injection Line – MEILONG Detail:

Alloy Feature

Incoloy alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum and copper. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Characteristics

Excellent resistance to reducing and oxidizing acids

Good resistance to stress-corrosion cracking

Satisfactory resistance to localized attack like pitting and crevice corrosion

Very resistant to sulfuric and phosphoric acids

Good mechanical properties at both room and elevated temperatures up to approximately 1020° F

Permission for pressure-vessel use at wall temperatures up to 800°F

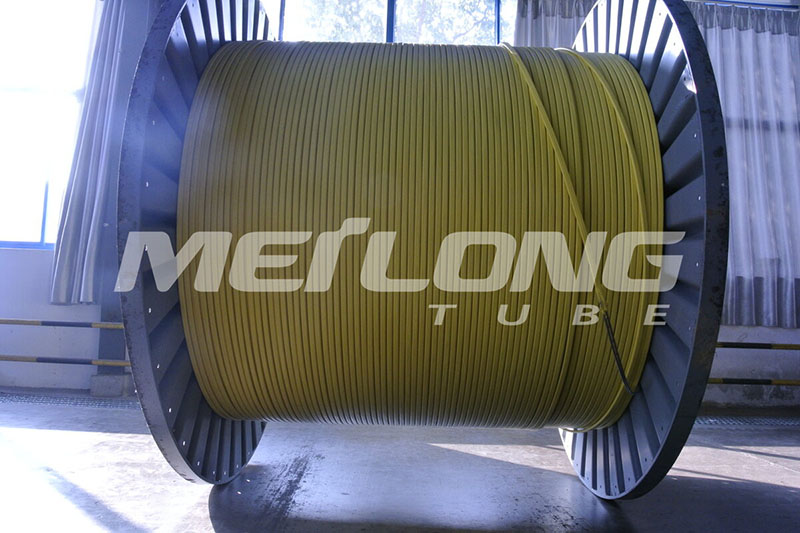

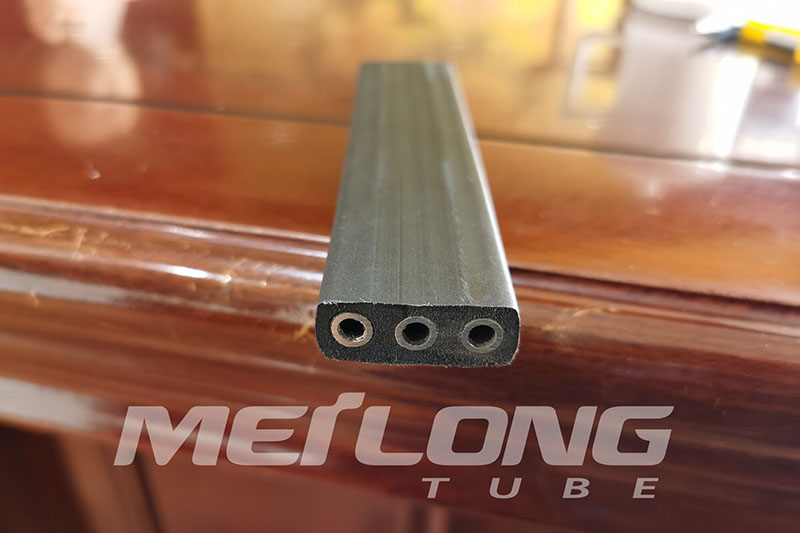

Product Display

Application

Chemical Processing

Pollution-control

Oil and gas well piping

Nuclear fuel reprocessing

Components in pickling equipment like heating coils, tanks, baskets and chains

Acid production

Encapsulation Features

Maximize protection of downhole line

Increase crush resistance during installation

Protect injection line against abrasion and pinching

Eliminate long term stress corrosion failure of control line

Improve clamping profile

Single or multiple encapsulation for ease of running and added protection

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients for Reasonable price Stainless Steel Capillary Tubing - Encapsulated Incoloy 825 Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Bangladesh, Nigeria, Miami, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!