Original Factory Alloy 825 Control Line - Incoloy 825 Control Line Flatpack – MEILONG

Original Factory Alloy 825 Control Line - Incoloy 825 Control Line Flatpack – MEILONG Detail:

Product Introduction

Meilong Tube’s downhole control lines are used primarily as communication conduits for hydraulically operated downhole devices in oil, gas, and water-injection wells, where durability and resistance to extreme harsh conditions are required. These lines can be custom configured for a variety of applications and downhole components.

All encapsulated materials are hydrolytically stable and are compatible with all typical well completion fluids, including high-pressure gas. The material selection is based on various criteria, including bottomhole temperature, hardness, tensile and tear strength, water absorption and gas permeability, oxidation, and abrasion and chemical resistance.

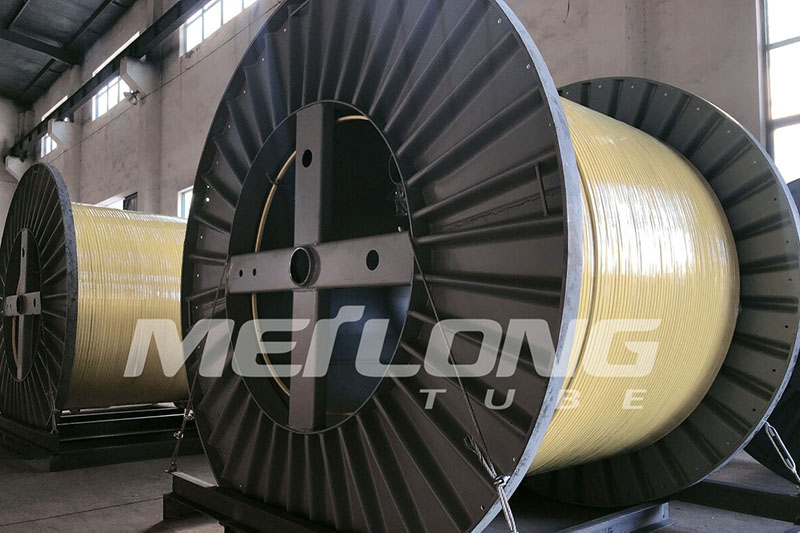

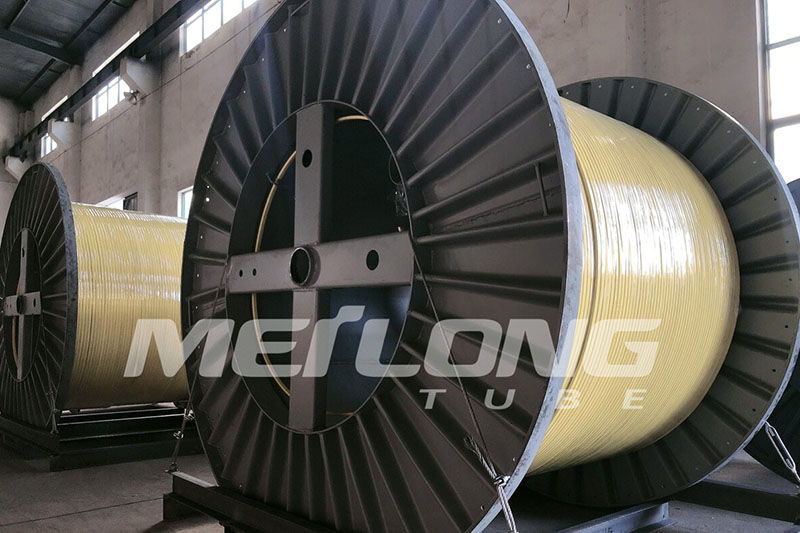

Product Display

Alloy Feature

Incoloy alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum and copper. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Characteristics

Excellent resistance to reducing and oxidizing acids

Good resistance to stress-corrosion cracking

Satisfactory resistance to localized attack like pitting and crevice corrosion

Very resistant to sulfuric and phosphoric acids

Good mechanical properties at both room and elevated temperatures up to approximately 1020° F

Permission for pressure-vessel use at wall temperatures up to 800°F

Application

Chemical Processing

Pollution-control

Oil and gas well piping

Nuclear fuel reprocessing

Components in pickling equipment like heating coils, tanks, baskets and chains

Acid production

Product detail pictures:

Related Product Guide:

It adheres to the tenet "Honest, industrious, enterprising, innovative" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for Original Factory Alloy 825 Control Line - Incoloy 825 Control Line Flatpack – MEILONG , The product will supply to all over the world, such as: Israel, Montpellier, Costa Rica, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.