Online Exporter Incoloy 825 Capillary Tube - PVDF Encapsulated Super Duplex 2507 Chemical Injection Line Tube – MEILONG

Online Exporter Incoloy 825 Capillary Tube - PVDF Encapsulated Super Duplex 2507 Chemical Injection Line Tube – MEILONG Detail:

Chemical Composition

Super Duplex 2507

|

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Nickel |

Chromium |

Molybdenum |

Nitrogen |

Copper |

|

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

|

max. |

|

0.03 |

1.20 |

0.035 |

0.020 |

0.80 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

0.24-0.32 |

0.5 |

Norm Equivalence

|

Grade |

UNS No |

Euro norm |

|

|

No |

Name |

||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 |

| 2507 | S32750 | 1.4410 | X2CrNiMoN25-7-4 |

Description

One of the main challenges in the upstream processes of the oil and gas industry is to protect pipeline and process equipment against waxes, scaling and asphalthane deposits. The engineering disciplines involved in flow assurance play an essential part in mapping the requirements that reduce or prevent loss of production due to pipeline or process equipment blockage. Coiled tubing from Meilong Tube is applied to umbilicals and chemical injection systems play an effective role in chemical storage and delivery at an optimizing flow assurance.

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction.

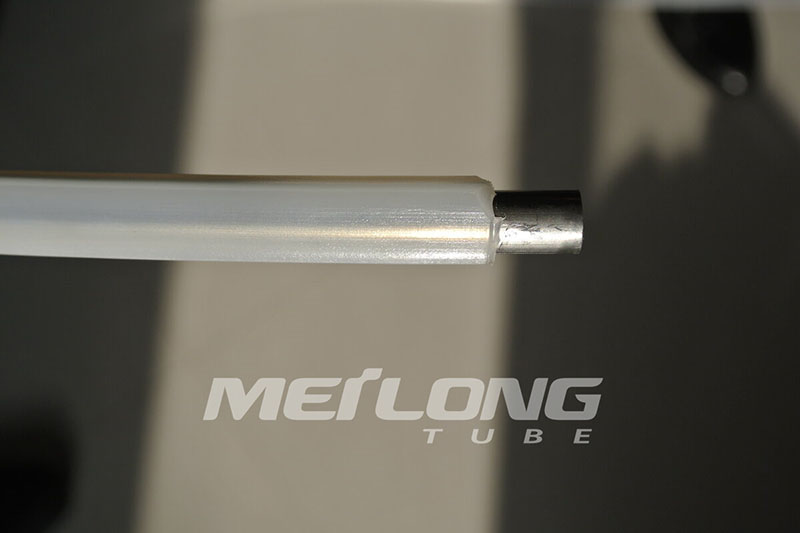

Product Display

Round Profiles of Single Line Encapsulation

| 1/4’’ OD line tubing | 0.433’’ Dia (11.0 mm) |

| 3/8’’ OD line tubing | 0.535’’ Dia (13.6 mm) |

| 1/2’’ OD line tubing | 0.660’’ Dia (16.8 mm) |

Square Profiles of Single Line Encapsulation

| 1/4’’ OD line tubing | 0.433’’ x 0.433’’ (11.0 mm x 11.0 mm) |

| 3/8’’ OD line tubing | 0.535’’ x 0.535’’ (13.6 mm x 13.6 mm) |

| 1/2’’ OD line tubing | 0.660’’ x 0.660’’ (16.8 mm x 16.8 mm) |

Product detail pictures:

Related Product Guide:

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Online Exporter Incoloy 825 Capillary Tube - PVDF Encapsulated Super Duplex 2507 Chemical Injection Line Tube – MEILONG , The product will supply to all over the world, such as: Casablanca, Sheffield, Finland, We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.