OEM manufacturer Alloy 625 Chemical Injection Tubing - Inconel 625 Chemical Injection Line Tubing – MEILONG

OEM manufacturer Alloy 625 Chemical Injection Tubing - Inconel 625 Chemical Injection Line Tubing – MEILONG Detail:

Product Introduction

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

Unique manufacturing capabilities and processes allow Meilong Tube to produce the longest continuous chemical injection line tubing available in stainless steels and high nickel alloys. Our long length tubing coils are used extensively for chemical injection in subsea and onshore wells. The length without orbital welds which reduces the potential for defects and failures. Additionally, our coils have an extremely clean and smooth inside surface that is ideal for chemical injection systems. The coils offer short hydraulic response time, greater collapse strength, and elimination of methanol permeation.

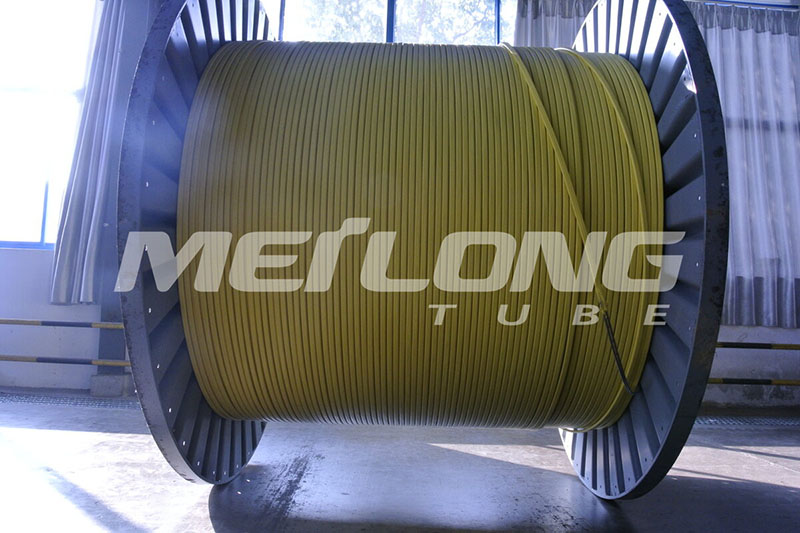

Product Display

Alloy Feature

Inconel 625 is a material with excellent resistance to pitting, crevice and corrosion cracking. Highly resistant in a wide range of organic and mineral acids. Good high temperature strength.

Application

Components where exposure to sea water and high mechanical stresses are required.

Oil and gas production where hydrogen sulfide and elementary sulfur exist at temperature in excess of 150C.

Components exposed to flue gas or in flue gas desulfurization plants.

Flare stacks on offshore oil platforms.

Hydrocarbon processing from tar-sand and oil-shale recovery projects.

Dimensional Tolerance

| ASTM B704 / ASME SB704, Inconel 625, UNS N06625 | ||

| ASTM B751 / ASME SB751 | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) | ±0.004’’ (±0.10 mm) | ±12.5% |

| 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) | ±0.0075’’ (±0.19 mm) | ±12.5% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) | ±0.004’’ (±0.10 mm) | ±10% |

| 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) | ±0.004’’ (±0.10 mm) | ±8% |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for OEM manufacturer Alloy 625 Chemical Injection Tubing - Inconel 625 Chemical Injection Line Tubing – MEILONG , The product will supply to all over the world, such as: Guatemala, Southampton, San Francisco, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!