OEM Manufacturer 316L Chemical Injection Tube - Monel 400 Chemical Injection Line Tubing – MEILONG

OEM Manufacturer 316L Chemical Injection Tube - Monel 400 Chemical Injection Line Tubing – MEILONG Detail:

Product Introduction

One of the main challenges in the upstream processes of the oil and gas industry is to protect pipeline and process equipment against waxes, scaling and asphalthane deposits. The engineering disciplines involved in flow assurance play an essential part in mapping the requirements that reduce or prevent loss of production due to pipeline or process equipment blockage. Coiled tubing from Meilong Tube is applied to umbilicals and chemical injection systems play an effective role in chemical storage and delivery at an optimizing flow assurance.

To assure produced fluid flow and protect your production infrastructure from plugging and corrosion, you need reliable injection lines for your production chemical treatments. Chemical injection lines from Meilong Tube help enhance the efficiency of your production equipment and lines, both downhole and at surface.

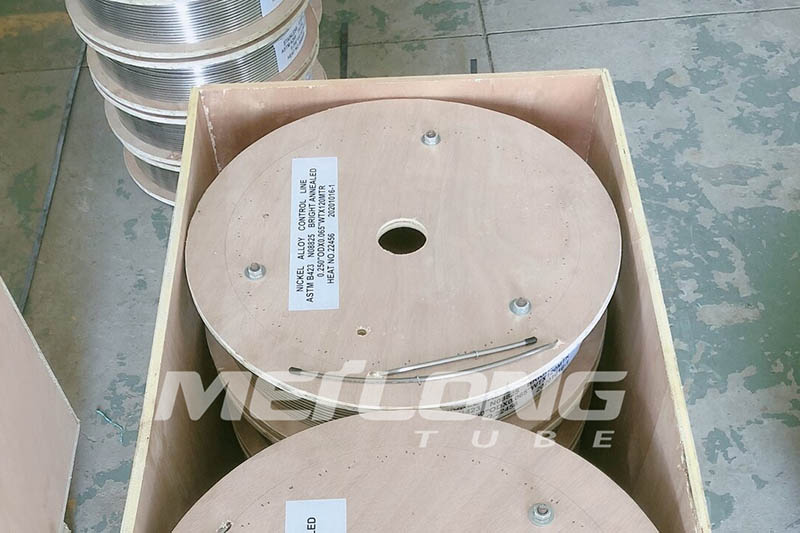

Product Display

Alloy Feature

As would be expected from its high copper content, alloy 400 is rapidly attacked by nitric acid and ammonia systems.

Monel 400 has great mechanical properties at subzero temperatures, can be used in temperatures up to 1000° F, and its melting point is 2370-2460° F. However, alloy 400 is low in strength in the annealed condition so, a variety of tempers may be used to increase the strength.

Dimensional Tolerance

| ASTM B165 / ASME SB165, Monel 400, UNS N04400 | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’ ≤OD<3/16’’ (3.18≤OD<4.76 mm) | +0.003’’ (+0.08 mm) / -0 | ±10% |

| 3/16’’≤OD<1/2’’ (15.88≤OD<12.7 mm) | +0.004’’ (+0.10 mm) / -0 | ±10% |

| 1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm) | +0.005’’ (+0.13 mm) / -0 | ±10% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’ ≤OD<3/16’’ (3.18≤OD<4.76 mm) | +0.003’’ (+0.08 mm) / -0 | ±10% |

| 3/16’’≤OD<1/2’’ (15.88≤OD<12.7 mm) | +0.004’’ (+0.10 mm) / -0 | ±10% |

| 1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm) | +0.004’’ (+0.10 mm) / -0 | ±8% |

Product detail pictures:

Related Product Guide:

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for OEM Manufacturer 316L Chemical Injection Tube - Monel 400 Chemical Injection Line Tubing – MEILONG , The product will supply to all over the world, such as: Florida, Moldova, Algeria, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!