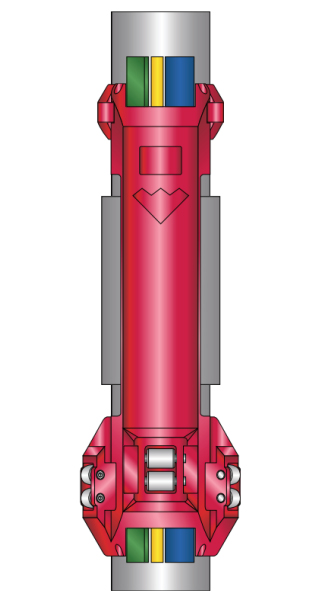

The type of roller cross-coupling control-line protector (CLP), known as the roller CLP, is designed to support and protect control lines as 3 1/2-in. tubing is run into casing in extended-reach wells. The roller CLP is positioned across tubing connections. The rollers reduce drag up to 45 percent by keeping control lines off the low side of the well so that tubing and control lines can run smoothly through the casing. This design allows intelligent completions in extended-reach wells where reaching total depth may otherwise be impossible.

Applications

• Intelligent completion installations that require hydraulic flow-control valves, electronic gauge systems, or optical sensing systems

• Horizontal or deviated extended-reach well completions that require drag reduction to reach total depth

Features, Advantages and Benefits

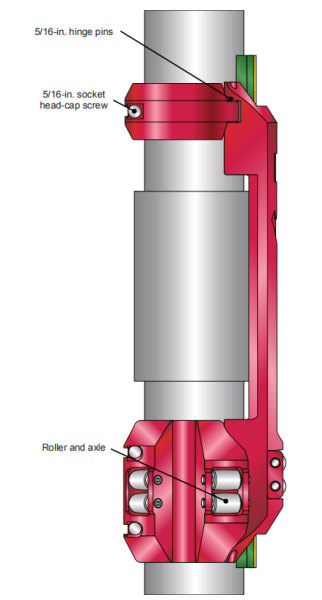

• The roller CLP fits securely across the tubing coupling to hold the control lines firmly in place, preventing damage to the lines and avoiding the need for expensive, time-consuming repairs or replacements.

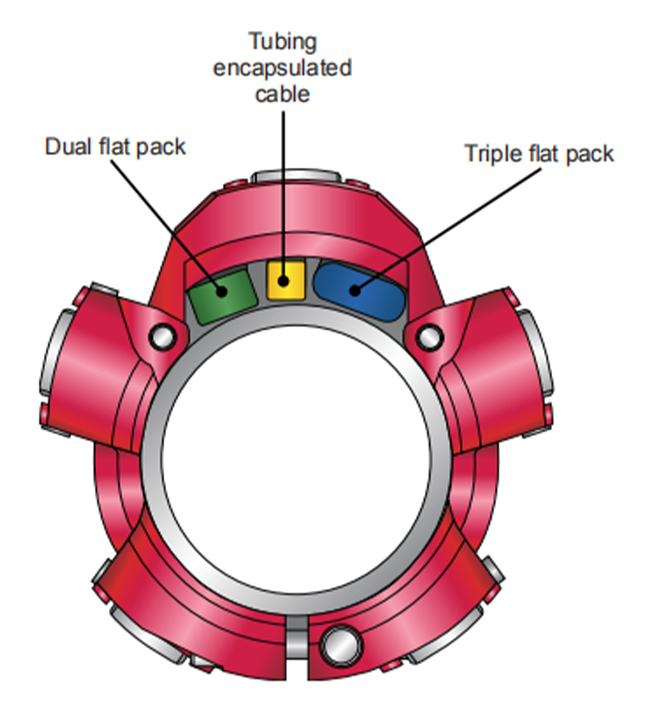

• The roller CLP fits over tubing couplings of varying lengths and ODs and also accomodates a triple flat pack (11mm x 27mm), a dual flat pack (11mm x 18mm), and a tubing encapsulated cable (11mm x 11mm), enabling use of the unit in a wide range of applications and minimizing the need for additional equipment.

• The leading and trailing edges of the roller CLP are angled to provide a smoother transition from 9 5/8- to 7-in. casing, improving operational efficiency and reducing costs.

• The roller CLP is installed with standard tools (including air-driven tools), expediting setup and reducing rig time.

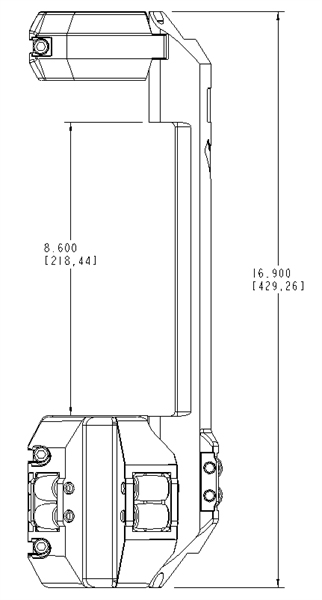

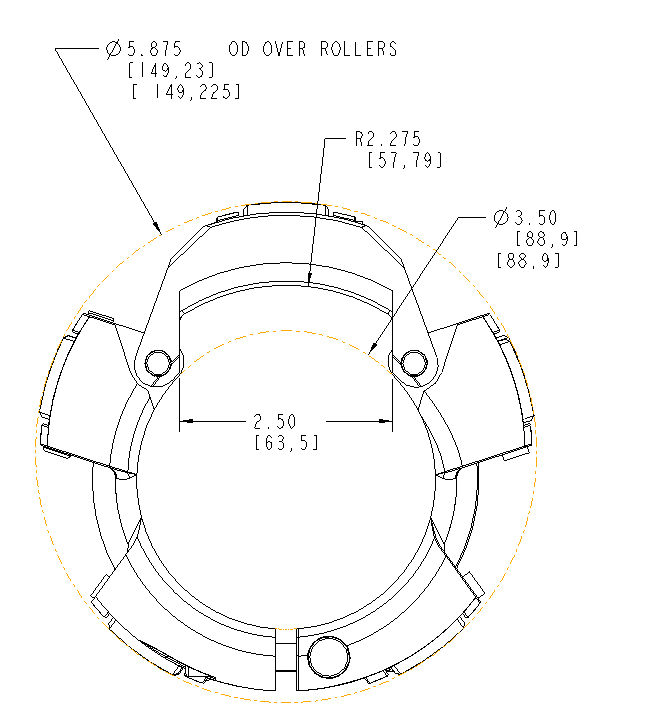

Specifications

| Tubing size (in.) |

3-1/2 |

| Casing size (in.) |

7 |

| Tool OD over roller (in./mm) |

5.875 149.23 |

| Roller diameter (in./mm) |

0.750 19.050 |

| Maximum coupling length (in./mm) |

8.000 203.2 |

| Maximum coupling OD (in./mm) |

4.500 114.3 |

Post time: Apr-08-2022