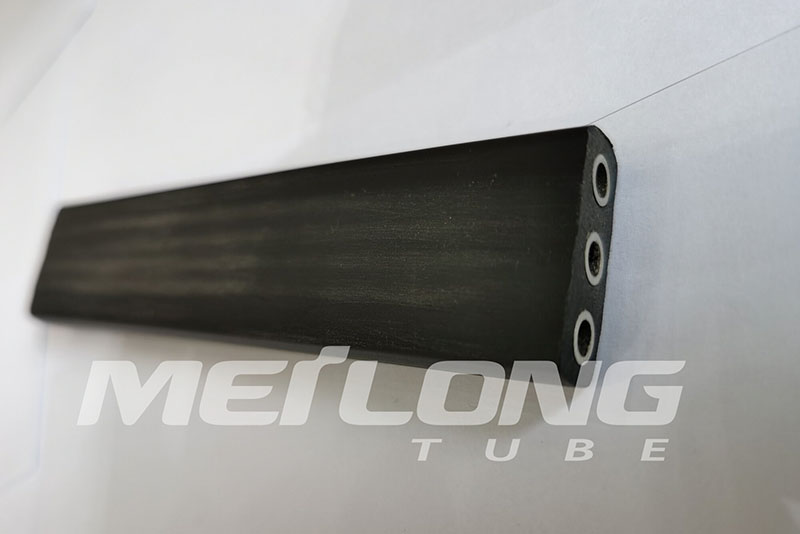

New Fashion Design for Hydraulic Control Line Flatpack Encapsulation - Monel 400 Hydraulic Control Line – MEILONG

New Fashion Design for Hydraulic Control Line Flatpack Encapsulation - Monel 400 Hydraulic Control Line – MEILONG Detail:

Product introduction

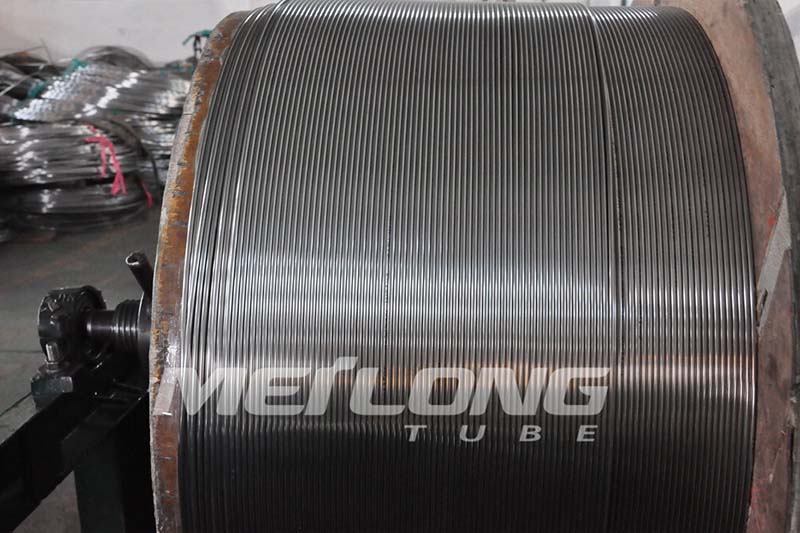

The tubing products for the oil & gas sector have been successfully applied in some of the most aggressive subsea and downhole conditions and we have a long proven track record of supplying products that meet the strict quality requirements of the oil and gas sector.

Meilong Tube offers coiled tubing in a wide range of corrosion resistant stainless steels, nickel alloys. We have extensive experience in product supply and innovation in this sector, from the technological advances required for subsea developments in the 1999 to the deepwater challenges of today

Product Display

Alloy Feature

As would be expected from its high copper content, alloy 400 is rapidly attacked by nitric acid and ammonia systems.

Monel 400 has great mechanical properties at subzero temperatures, can be used in temperatures up to 1000° F, and its melting point is 2370-2460° F. However, alloy 400 is low in strength in the annealed condition so, a variety of tempers may be used to increase the strength.

Characteristics

Corrosion resistance in an extensive range of marine and chemical environments. From pure water to non-oxidizing mineral acids, salts and alkalis.

This alloy is more resistant to nickel under reducing conditions and more resistant than copper under oxidizing conditions, it does show however better resistance to reducing media than oxidizing.

Good mechanical properties from subzero temperatures up to about 480C.

Good resistance to sulfuric and hydrofluoric acids. Aeration however will result in increased corrosion rates. May be used to handle hydrochloric acid, but the presence of oxidizing salts will greatly accelerate corrosive attack.

Resistance to neutral, alkaline and acid salts is shown, but poor resistance is found with oxidizing acid salts such as ferric chloride.

Excellent resistance to chloride ion stress corrosion cracking.

Chemical Composition

|

Nickel |

Copper |

Iron |

Manganese |

Carbon |

Silicon |

Sulfur |

|

% |

% |

% |

% |

% |

% |

% |

|

min. |

|

max. |

max. |

max. |

max. |

max. |

|

63.0 |

28.0-34.0 |

2.5 |

2.0 |

0.3 |

0.5 |

0.024 |

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for New Fashion Design for Hydraulic Control Line Flatpack Encapsulation - Monel 400 Hydraulic Control Line – MEILONG , The product will supply to all over the world, such as: San Francisco, Germany, luzern, The quality of our products is equal to OEM's quality, because our core parts are the same with OEM supplier. The above products have passed professional certification, and we not only can produce OEM-standard products but we also accept Customized Products order.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.