New Arrival China Duplex Stainless Steel Control Line - Encapsulated Control Line Flatpack – MEILONG

New Arrival China Duplex Stainless Steel Control Line - Encapsulated Control Line Flatpack – MEILONG Detail:

Product Introduction

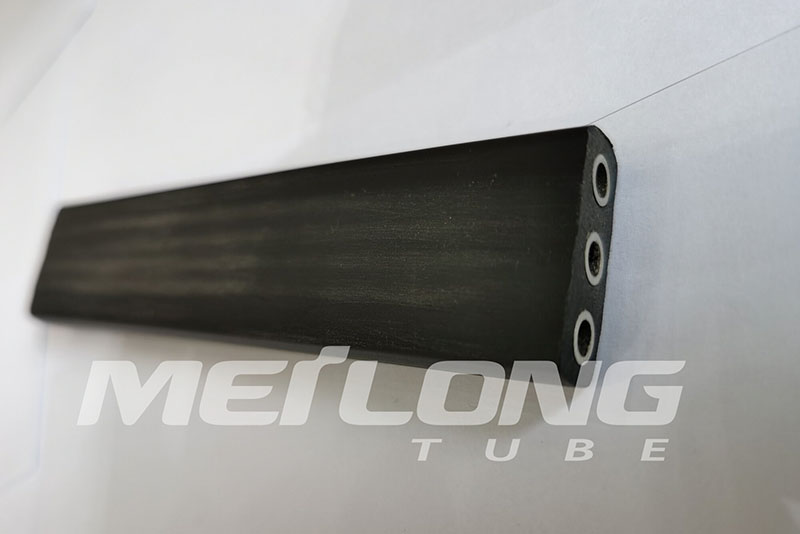

Encapsulation provides a protective layer to keep the lines from being scratched, dented, and possibly crushed while running in hole.

Encapsulation of several components (Flat Pack) provides a consolidation that will help reduce equipment and personnel that is needed to deploy multiple single components. In many cases, a flat pack is mandatory as rig space can be limited.

Encapsulation keeps from metal to metal contact.

Encapsulation can provide protection to underlying components while in hole such as a lines that can be across a sand face or possibly in contact with a high rate of gas.

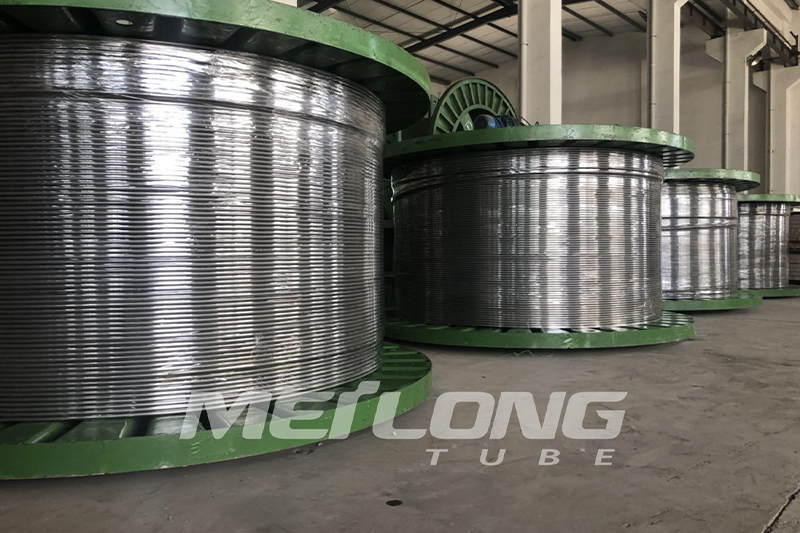

FREE OF ORBITAL WELDS

Hydraulic Control Lines depending on the length of the application are subjected to raw materials. Orbital welds have become unnecessary in our industry as well completions are often greater than the standard yield of a mill produced coil. Our seam-welded tubing production uses Tungsten Inert Gas (TIG) welding machines. This process gives the operator the tools to perform a repeatable, high-quality weld. Our current equipment, together with cold-drawing machines allow us to produce OD Size ranges of 1/8” – 1” and Wall Thicknesses of 0.028” -0.095”. Common alloys for tubing products are 316L, 2205, 2507, 825, 625, and Monel 400.

NDT

We perform a variety of tests to validate the integrity of our products.

Eddy current test

Pressure Testing

Liquid – A variety of capabilities for different specification tubing.

Product Display

Application

MEILONG offers a range of industry standard control line tubing encapsulated in a variety of materials, such as polyurethane, polyethylene and polypropylene. The specified tubing material within these encapsulations is available in a range of sizes and colors for a variety of applications.

Down hole tubes; Subsea umbilical’s; Process constructions; General control system; Steam supply lines; Gas transport lines; Instrumentation

Product detail pictures:

Related Product Guide:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for New Arrival China Duplex Stainless Steel Control Line - Encapsulated Control Line Flatpack – MEILONG , The product will supply to all over the world, such as: Serbia, Milan, Oman, To work with an excellent products manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,