New Arrival China Duplex Stainless Steel Control Line - Control Line Flatpack – MEILONG

New Arrival China Duplex Stainless Steel Control Line - Control Line Flatpack – MEILONG Detail:

Alloy Materials

| Austenitic: | 316L | ASTM A-269 |

| Duplex: | S31803/S32205; S32750 | ASTM A-789; ASTM A-789 |

| Nickel alloy: | N08825N06625 | ASTM B-704; ASTM B-423ASTM B-704; ASTM B-444 |

| CuNi alloy | Monel 400 | ASTM B-730; ASTM B-165 |

Product Display

Application

In most cases, it is mandatory to have a means of closure for all wells capable of natural flow to the surface. The installation of a subsurface safety valve (SSSV) will provide this emergency closure capability. Safety systems may be operated on a fail-safe principle from a control panel located on the surface.

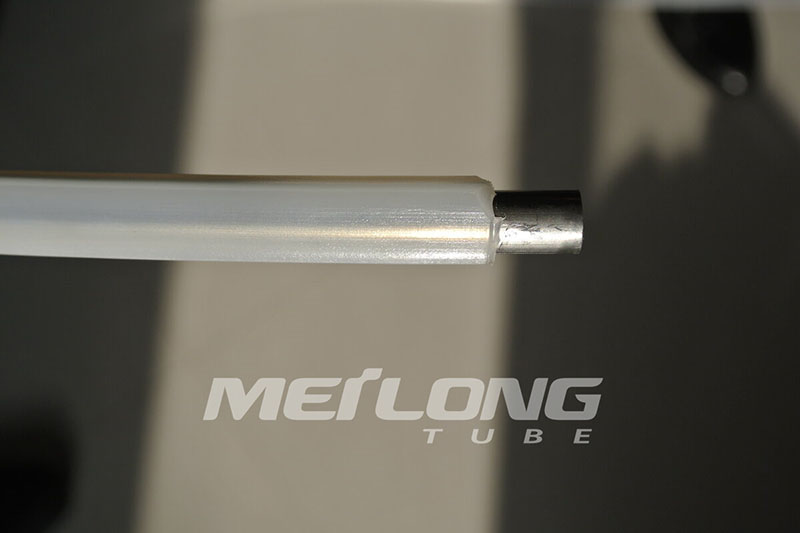

The SCSSV is controlled by a ¼” stainless steel control line that is attached to the outside of the well tubing string and installed when the production tubing is installed. Depending on the wellhead pressure, it may be necessary to keep as much as 10,000 psi on the control line to keep the valve open.

Other applications:

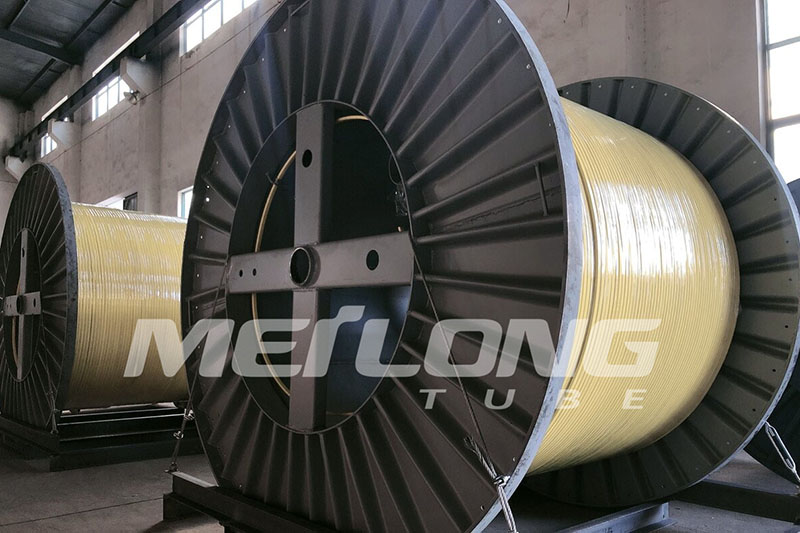

Capillary coiled alloy tubing for chemical injection

Bare and encapsulated hydraulic control line coiled alloy tubing for subsea safety valves

Velocity strings, work strings, and steel tube umbilicals

Geothermal coiled alloy tubing

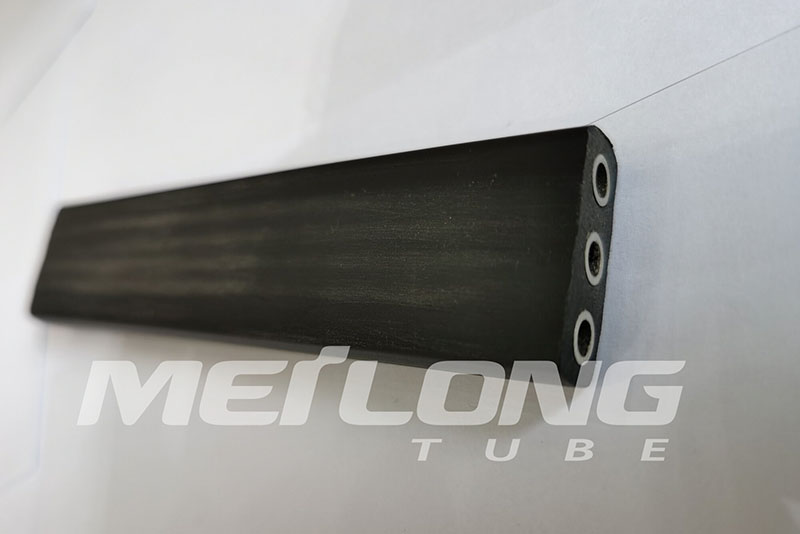

Encapsulation Features

Maximize protection of downhole line

Increase crush resistance during installation

Protect control line against abrasion and pinching

Eliminate long term stress corrosion failure of control line

Improve clamping profile

Single or multiple encapsulation for ease of running and added protection

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for New Arrival China Duplex Stainless Steel Control Line - Control Line Flatpack – MEILONG , The product will supply to all over the world, such as: Cannes, Lebanon, Sri Lanka, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.