Manufactur standard Super Duplex 2507 Hydraulic Control Line Tubing - Incoloy 825 Hydraulic Control Line – MEILONG

Manufactur standard Super Duplex 2507 Hydraulic Control Line Tubing - Incoloy 825 Hydraulic Control Line – MEILONG Detail:

Product introduction

Meilong Tube supplies a whole range of products to the oil and gas sector, and it’s one of our most important markets. You’ll find our high performance tubes successfully used in some of the most aggressive subsea and downhole conditions thanks to our proven track record in meeting the strict quality requirements of the oil, gas and geothermal energy industries.

Technical Datasheet

| Alloy |

O.D. |

W.T. |

Yield Strength | Tensile Strength | Elongation | Hardness | Working Pressure | Burst Pressure | Collapse Pressure |

|

inch |

inch |

MPa | MPa | % | HV | psi | psi | psi | |

|

|

|

min. | min. | min. | max. | min. | min. | min. | |

| Incoloy 825 |

0.250 |

0.035 |

241 | 586 | 30 | 209 | 7,627 | 29,691 | 9,270 |

| Incoloy 825 |

0.250 |

0.049 |

241 | 586 | 30 | 209 | 11,019 | 42,853 | 12,077 |

| Incoloy 825 |

0.250 |

0.065 |

241 | 586 | 30 | 209 | 15,017 | 58,440 | 14,790 |

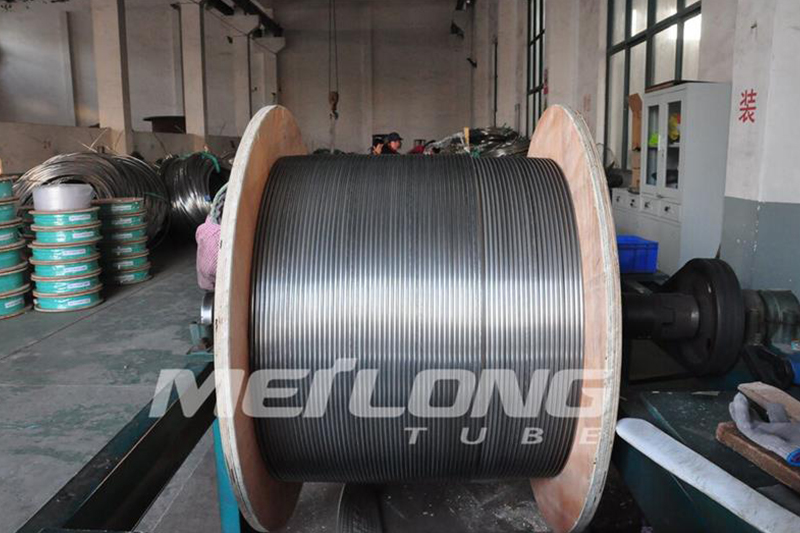

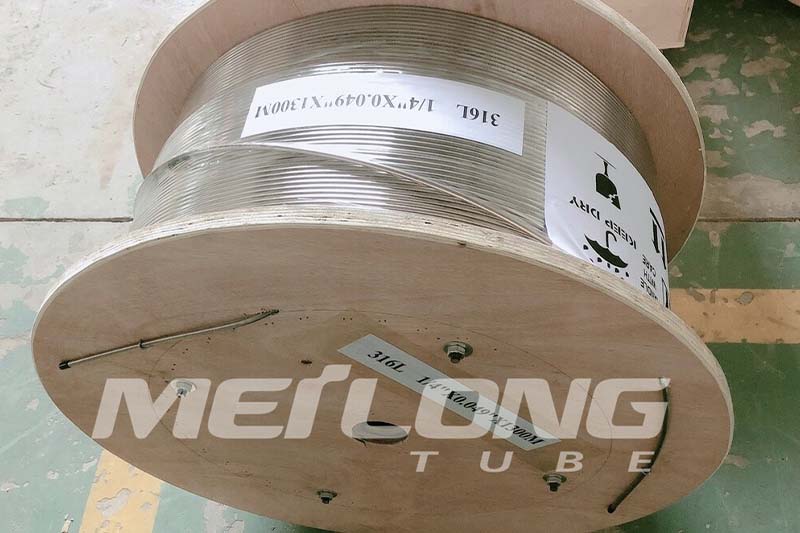

Product Display

Alloy Feature

Characteristics

Excellent resistance to reducing and oxidizing acids.

Good resistance to stress-corrosion cracking.

Satisfactory resistance to localized attack like pitting and crevice corrosion.

Very resistant to sulfuric and phosphoric acids.

Good mechanical properties at both room and elevated temperatures up to approximately 1020° F.

Permission for pressure-vessel use at wall temperatures up to 800°F.

Application

Chemical Processing.

Pollution-control.

Oil and gas well piping.

Nuclear fuel reprocessing.

Components in pickling equipment like heating coils, tanks, baskets and chains.

Acid production.

Product detail pictures:

Related Product Guide:

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Manufactur standard Super Duplex 2507 Hydraulic Control Line Tubing - Incoloy 825 Hydraulic Control Line – MEILONG , The product will supply to all over the world, such as: Washington, Russia, Niger, Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!