Hot sale Stainless Steel Capillary Tube - Santoprene TPV Encapsulated N08825 Chemical Injection Line – MEILONG

Hot sale Stainless Steel Capillary Tube - Santoprene TPV Encapsulated N08825 Chemical Injection Line – MEILONG Detail:

Testing Abilities

| Chemical | Flare | Metallurgical |

| Corrosion | Flatten | Positive material identification (PMI) |

| Dimensional | Grain size | Surface roughness |

| Eddy current | Hardness | Tensile |

| Elongation | Hydrostatic | Yield |

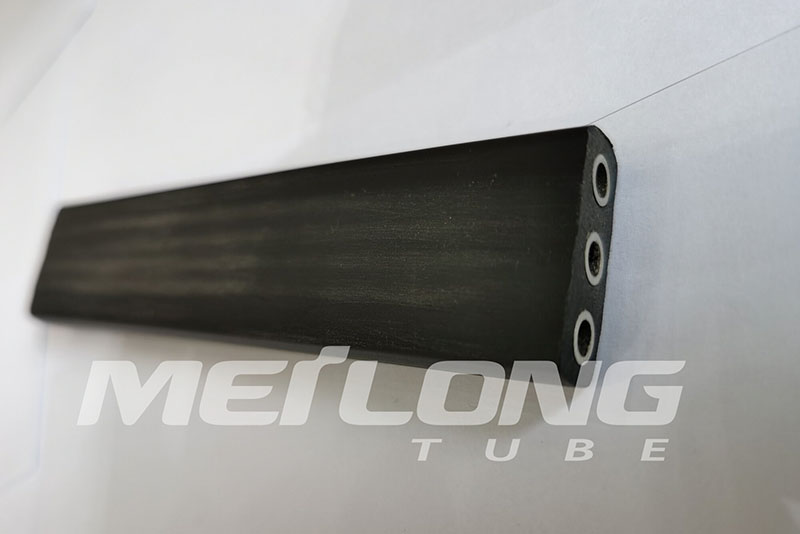

Product Display

Profile Of Single Line Encapsulation

| Round Profiles of Single Line Encapsulation | |

| 1/4’’ OD line tubing | 0.433’’ Dia (11.0 mm) |

| 3/8’’ OD line tubing | 0.535’’ Dia (13.6 mm) |

| 1/2’’ OD line tubing | 0.660’’ Dia (16.8 mm) |

Alloy Feature

Characteristics

Excellent resistance to reducing and oxidizing acids

Good resistance to stress-corrosion cracking

Satisfactory resistance to localized attack like pitting and crevice corrosion

Very resistant to sulfuric and phosphoric acids

Good mechanical properties at both room and elevated temperatures up to approximately 1020° F

Permission for pressure-vessel use at wall temperatures up to 800°F

Application

Chemical Processing

Pollution-control

Oil and gas well piping

Nuclear fuel reprocessing

Components in pickling equipment like heating coils, tanks, baskets and chains

Acid production

Dimensional Tolerance

| ASTM B423 / ASME SB423, Incoloy 825, UNS N08825 | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’≤OD<3/16’’ (3.18≤OD<4.76 mm) | +0.003’’ (+0.08 mm) / -0 | ±10% |

| 3/16≤OD<1/2’’ (4.76≤OD<12.7 mm) | +0.004’’ (+0.10 mm) / -0 | ±10% |

| 1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm) | +0.005’’ (+0.13 mm) / -0 | ±10% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’ ≤OD<3/16’’ (3.18≤OD<4.76 mm) | +0.003’’ (+0.08 mm) / -0 | ±10% |

| 3/16≤OD<1/2’’ (4.76≤OD<12.7 mm) | +0.004’’ (+0.10 mm) / -0 | ±10% |

| 1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm) | +0.004’’ (+0.10 mm) / -0 | ±8% |

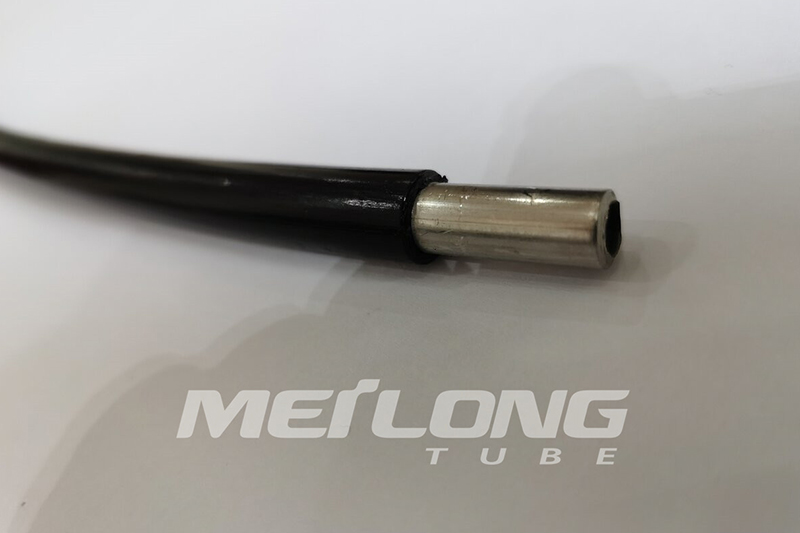

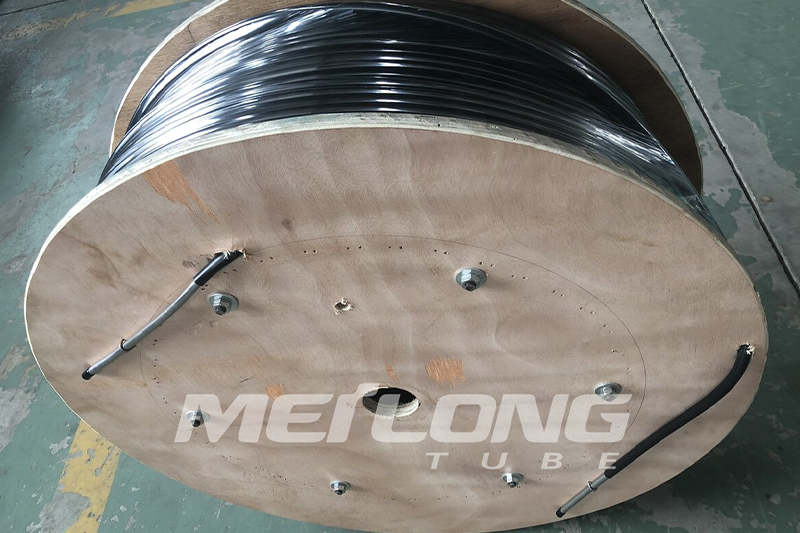

Product detail pictures:

Related Product Guide:

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for Hot sale Stainless Steel Capillary Tube - Santoprene TPV Encapsulated N08825 Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Philadelphia, Albania, Finland, Our items have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll supply the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

Write your message here and send it to us