Good quality Chemical Injection Line - Monel 400 Capillary Tube Chemical Injection Line – MEILONG

Good quality Chemical Injection Line - Monel 400 Capillary Tube Chemical Injection Line – MEILONG Detail:

Testing Abilities

| Chemical | Flare | Metallurgical |

| Corrosion | Flatten | Positive material identification (PMI) |

| Dimensional | Grain size | Surface roughness |

| Eddy current | Hardness | Tensile |

| Elongation | Hydrostatic | Yield |

Application

In all fields of the oil and gas industry, chemicals are injected into process lines and fluids. Take oilfield services, chemicals are used to film the side of the wellbore for improved stability. In pipelines they avoid build-up and keep the infrastructure healthy.

Other Application:

In the oil and gas industry we inject chemicals in order.

To protect the infrastructure.

To optimize processes.

To assure flow.

And to improve productivity.

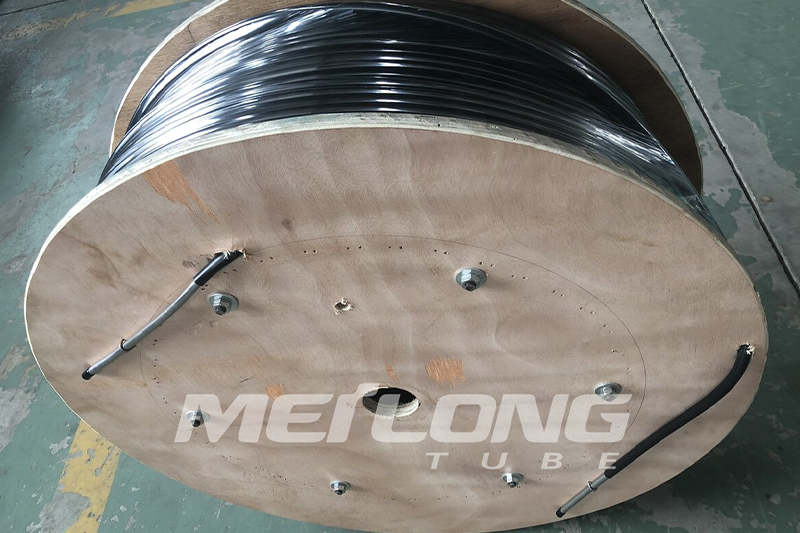

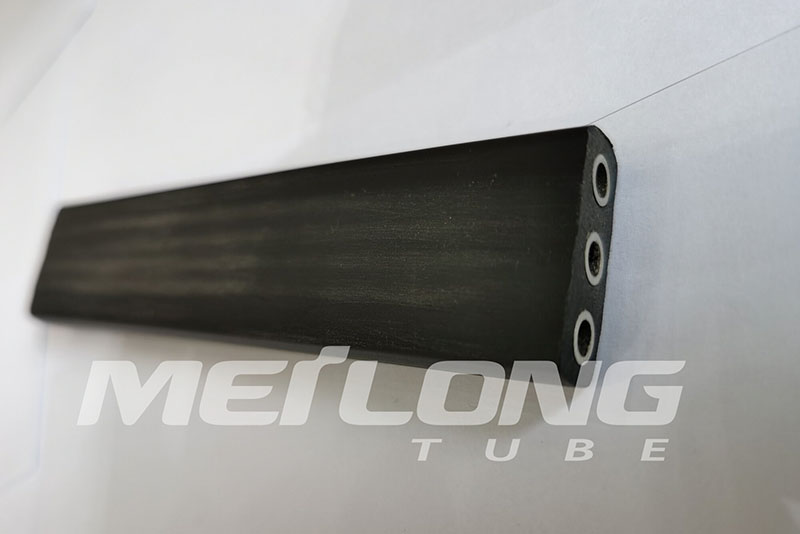

Product Display

Alloy Feature

Characteristics

Corrosion resistance in an extensive range of marine and chemical environments. From pure water to non-oxidizing mineral acids, salts and alkalis.

This alloy is more resistant to nickel under reducing conditions and more resistant than copper under oxidizing conditions, it does show however better resistance to reducing media than oxidizing.

Good mechanical properties from subzero temperatures up to about 480C.

Good resistance to sulfuric and hydrofluoric acids. Aeration however will result in increased corrosion rates. May be used to handle hydrochloric acid, but the presence of oxidizing salts will greatly accelerate corrosive attack.

Resistance to neutral, alkaline and acid salts is shown, but poor resistance is found with oxidizing acid salts such as ferric chloride.

Excellent resistance to chloride ion stress corrosion cracking.

Chemical Composition

|

Nickel |

Copper |

Iron |

Manganese |

Carbon |

Silicon |

Sulfur |

|

% |

% |

% |

% |

% |

% |

% |

|

min. |

|

max. |

max. |

max. |

max. |

max. |

|

63.0 |

28.0-34.0 |

2.5 |

2.0 |

0.3 |

0.5 |

0.024 |

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for Good quality Chemical Injection Line - Monel 400 Capillary Tube Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Belgium, Indonesia, New Orleans, Our technical expertise, customer-friendly service, and specialized merchandise make us/company name the first choice of customers and vendors. We've been looking for your inquiry. Let's set up the cooperation right now!

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.