Factory wholesale Incoloy 825 Hydraulic Control Line Tubing - Monel 400 Hydraulic Control Line Tube – MEILONG

Factory wholesale Incoloy 825 Hydraulic Control Line Tubing - Monel 400 Hydraulic Control Line Tube – MEILONG Detail:

Product introduction

● Each one tubing coil is a completely continuous length without orbital welds.

● Each one tubing coil is hydrostatic tested with a targeted pressure.

● The test can be witnessed on site by the third party inspectors (SGS, BV, DNV).

● Other tests are eddy current test, chemicals, flattening, flaring, tensile, yield, elongation, hardness for the material quality.

Tubing Process and Packing

1. Seamless: pierced, redrawn, annealed (multi-pass circulation process)

2. Welded: longitudinally welded, redrawn, annealed (multi-pass circulation process)

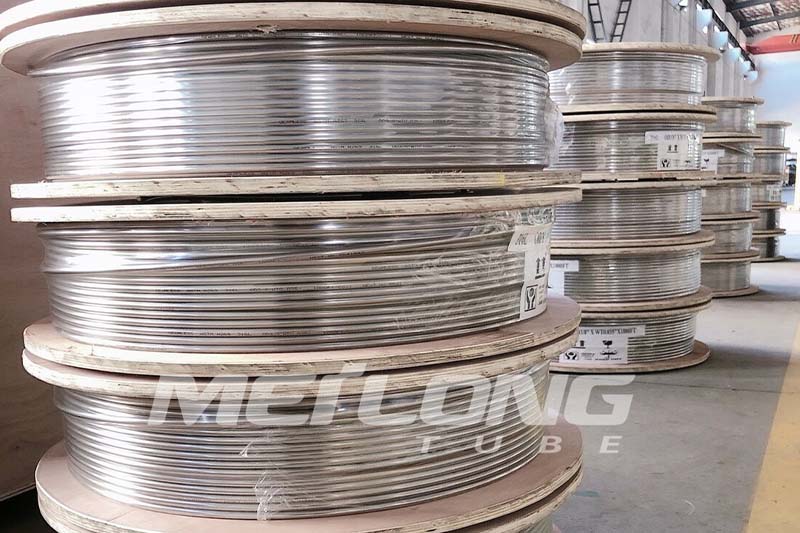

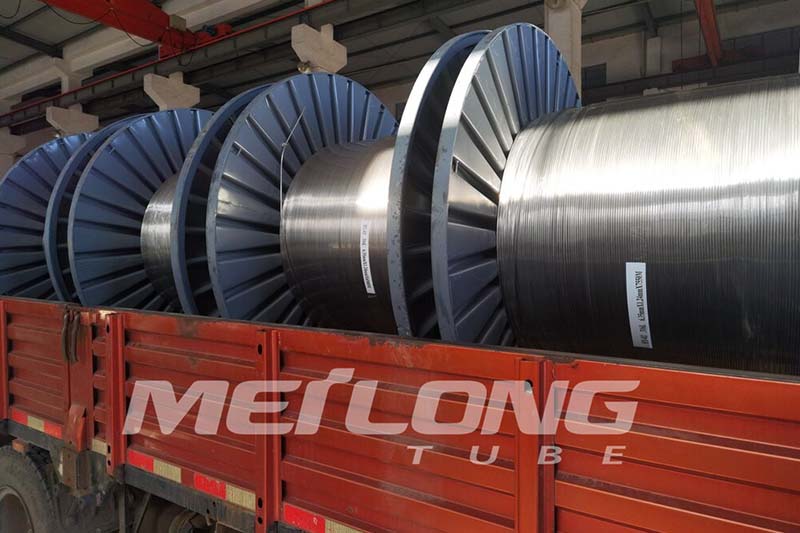

3. Packing: Tubing is level wound coiled on the metal / wooden drums or spools.

4. All drums or spools are packed in wooden crates for easy logistic operation.

Product Display

Alloy Feature

Monel 400 is a nickel-copper alloy (about 67% Ni – 23% Cu) that is resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated.

Application

Feed water and steam generator tubing.

Brine heaters, sea water scrubbers in tanker inert gas systems.

Sulfuric acid and hydrofluoric acid alkylation plants.

Pickling bat heating coils.

Heat exchanger tubing in a variety of industries.

Transfer piping from oil refinery crude columns.

Plant for the refining of uranium and isotope separation in the production of nuclear fuel.

Pumps and valves used in the manufacture of perchlorethylene, chlorinated plastics.

Monoethanolamine (MEA) reboiling tube.

Cladding for the upper areas of oil refinery crude columns.

Propeller and pump shafts.

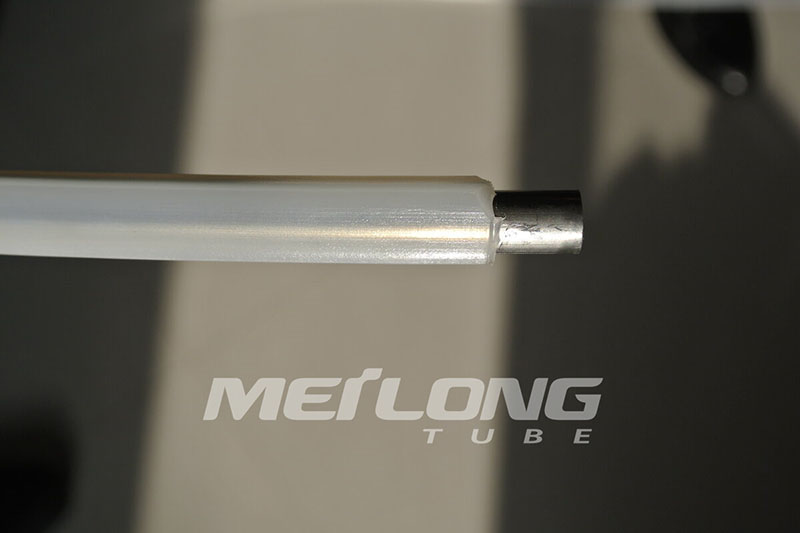

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for Factory wholesale Incoloy 825 Hydraulic Control Line Tubing - Monel 400 Hydraulic Control Line Tube – MEILONG , The product will supply to all over the world, such as: Colombia, French, Salt Lake City, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.