Factory wholesale Alloy 625 Hydraulic Control Line - Monel 400 Control Line – MEILONG

Factory wholesale Alloy 625 Hydraulic Control Line - Monel 400 Control Line – MEILONG Detail:

Product introduction

Meilong Tube offers coiled tubing in a wide range of corrosion resistant stainless steels, nickel alloys. We have extensive experience in product supply and innovation in this sector, from the technological advances required for subsea developments in the 1999 to the deepwater challenges of today

Alloy Feature

Monel 400 is a nickel-copper alloy (about 67% Ni – 23% Cu) that is resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated.

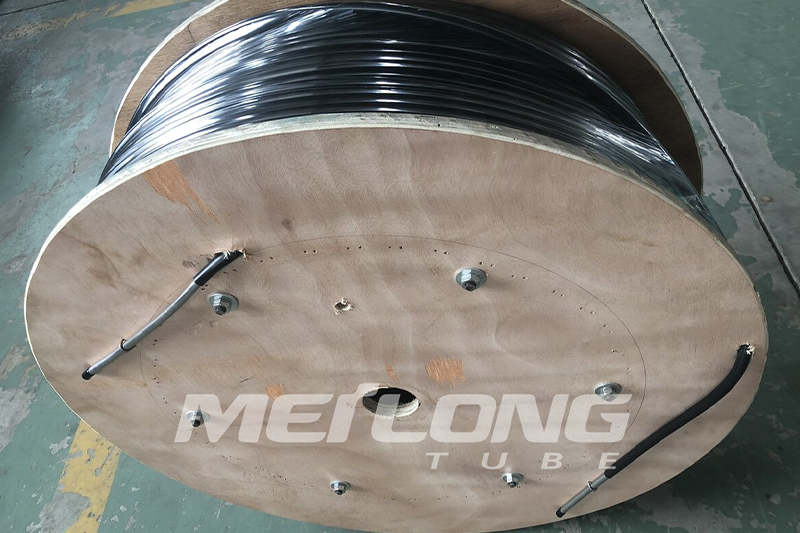

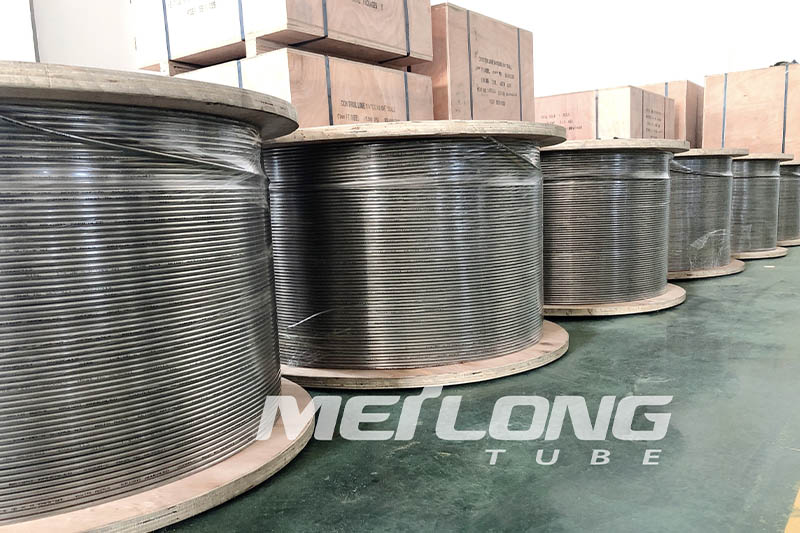

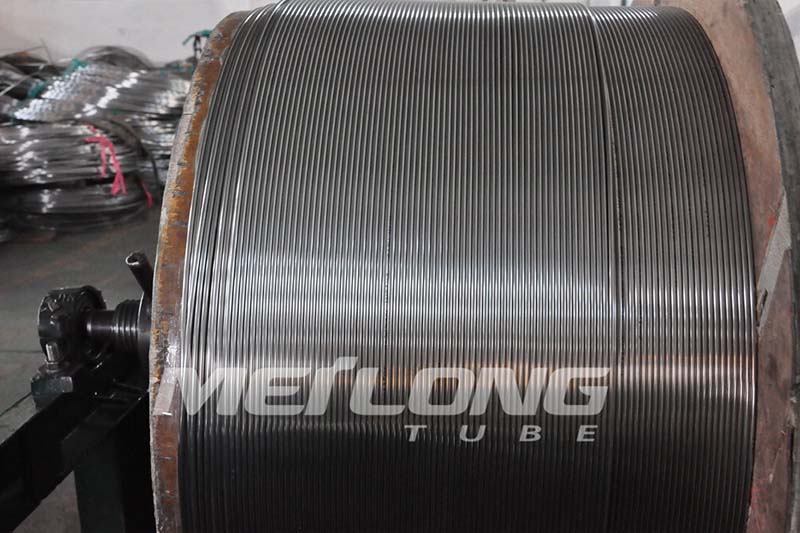

Product Display

Typical Tubing Size

Outside diameter of control lines is mainly 1/4’’ (6.35mm).

Wall thicknesses: 0.035’’ (0.89mm), 0.049’’ (1.24mm), 0.065’’ (1.65mm).

Control line tubing is available in lengths from 400 feet (122 meters) to 32,808 feet (10,000 meters). No orbitally butt welds.

Other specifications (1/8’’ to 3/4’’) are available on request.

|

Imperial size |

Metric size |

||

|

OD inch |

WT inch |

OD mm |

WT mm |

|

1/8 (0.125) |

0.028 |

3.18 |

0.71 |

|

0.035 |

3.18 |

0.89 |

|

|

3/16 (0.188) |

0.028 |

4.76 |

0.71 |

|

0.035 |

4.76 |

0.89 |

|

|

0.049 |

4.76 |

1.24 |

|

|

1/4 (0.250) |

0.035 |

6.35 |

0.89 |

|

0.049 |

6.35 |

1.24 |

|

|

0.065 |

6.35 |

1.65 |

|

|

0.083 |

6.35 |

2.11 |

|

|

3/8 (0.375) |

0.035 |

9.53 |

0.89 |

|

0.049 |

9.53 |

1.24 |

|

|

0.065 |

9.53 |

1.65 |

|

|

0.083 |

9.53 |

2.11 |

|

|

1/2 (0.500) |

0.035 |

12.7 |

0.89 |

|

0.049 |

12.7 |

1.24 |

|

|

0.065 |

12.7 |

1.65 |

|

|

0.083 |

12.7 |

2.11 |

|

Product detail pictures:

Related Product Guide:

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for Factory wholesale Alloy 625 Hydraulic Control Line - Monel 400 Control Line – MEILONG , The product will supply to all over the world, such as: Belarus, America, Frankfurt, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!