Factory selling Alloy 825 Hydraulic Control Line Tube - Inconel 625 Hydraulic Control Line – MEILONG

Factory selling Alloy 825 Hydraulic Control Line Tube - Inconel 625 Hydraulic Control Line – MEILONG Detail:

Product Introduction

Welded Control Lines are the preferred construction for control lines being used in downhole oil and gas applications. Our welded control lines are used in SCSSV, Chemical Injection, Advanced Well Completions, and Gauge Applications. We offer a variety of control lines. (TIG Welded, and floating plug drawn, and lines with enhancements) The various processes provide us the ability to customize a solution to meet your well completion.

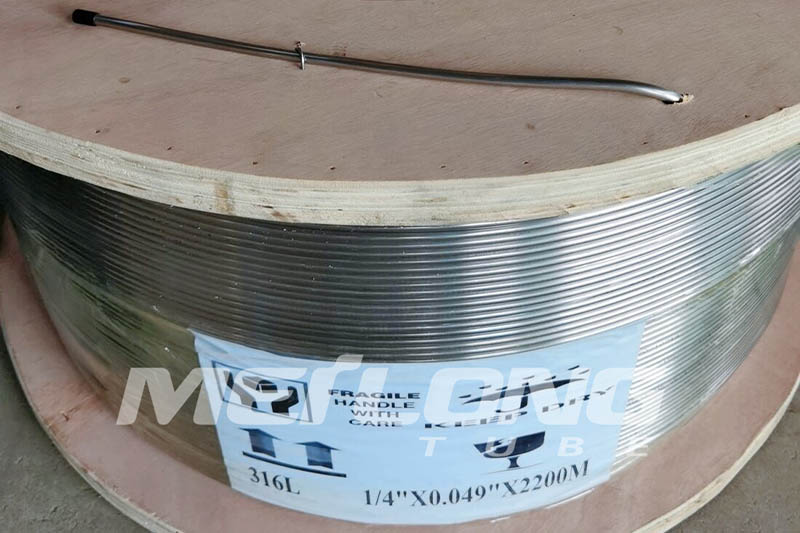

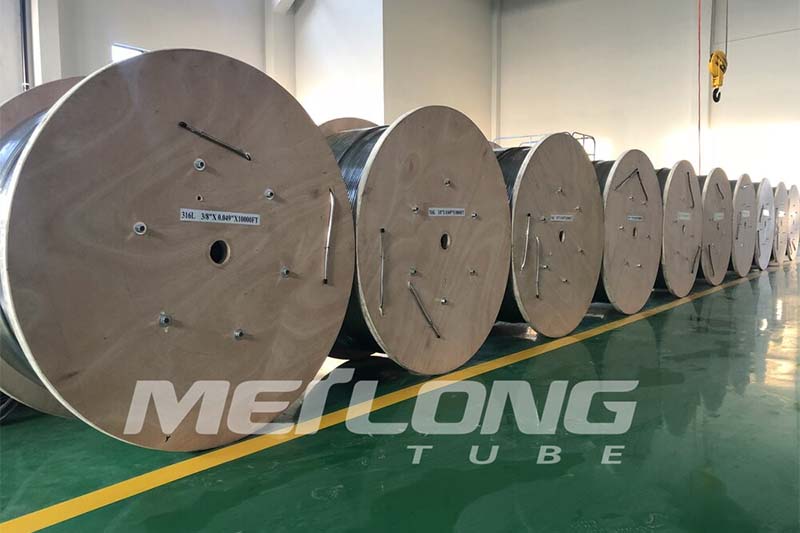

Product Display

Alloy Feature

Inconel 625 is a material with excellent resistance to pitting, crevice and corrosion cracking. Highly resistant in a wide range of organic and mineral acids. Good high temperature strength.

Characteristics

Excellent mechanical properties at both extremely low and extremely high temperatures.

Outstanding resistance to pitting, crevice corrosion and intercrystalline corrosion.

Almost complete freedom from chloride induced stress corrosion cracking.

High resistance to oxidation at elevated temperatures up to 1050C.

Good resistance to acids, such as nitric, phosphoric, sulfuric and hydrochloric, as well as to alkalis makes possible the construction of thin structural parts of high heat transfer.

Application

Components where exposure to sea water and high mechanical stresses are required.

Oil and gas production where hydrogen sulfide and elementary sulfur exist at temperature in excess of 150C.

Components exposed to flue gas or in flue gas desulfurization plants.

Flare stacks on offshore oil platforms.

Hydrocarbon processing from tar-sand and oil-shale recovery projects.

Technical Datasheet

|

Alloy |

O.D. |

W.T. |

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Working Pressure |

Burst Pressure |

Collapse Pressure |

|

inch |

inch |

MPa |

MPa |

% |

HV |

psi |

psi |

psi |

|

|

|

|

min. |

min. |

min. |

max. |

min. |

min. |

min. |

|

|

Inconel 625 |

0.250 |

0.035 |

414 |

827 |

30 |

266 |

13,112 |

41,896 |

15,923 |

|

Inconel 625 |

0.250 |

0.049 |

414 |

827 |

30 |

266 |

18,926 |

60,466 |

20,756 |

|

Inconel 625 |

0.250 |

0.065 |

414 |

827 |

30 |

266 |

25,806 |

82,467 |

25,399 |

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Factory selling Alloy 825 Hydraulic Control Line Tube - Inconel 625 Hydraulic Control Line – MEILONG , The product will supply to all over the world, such as: South Korea, Nigeria, Mozambique, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our items, just try to contact us for more details!

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.