Excellent quality Chemical Injection Line Tube - Capillary Tube Chemical Injection Line – MEILONG

Excellent quality Chemical Injection Line Tube - Capillary Tube Chemical Injection Line – MEILONG Detail:

Product introduction

To assure produced fluid flow and protect your production infrastructure from plugging and corrosion, you need reliable injection lines for your production chemical treatments. Chemical injection lines from Meilong Tube help enhance the efficiency of your production equipment and lines, both downhole and at surface.

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction, geothermal power generation.

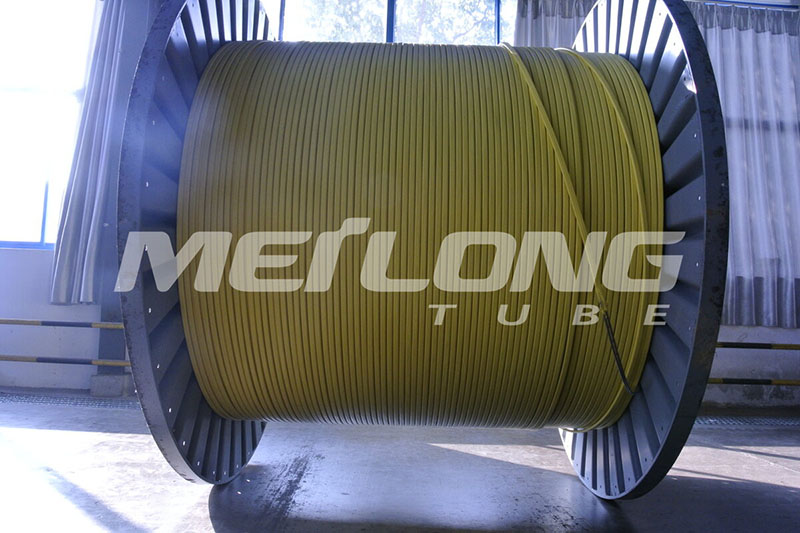

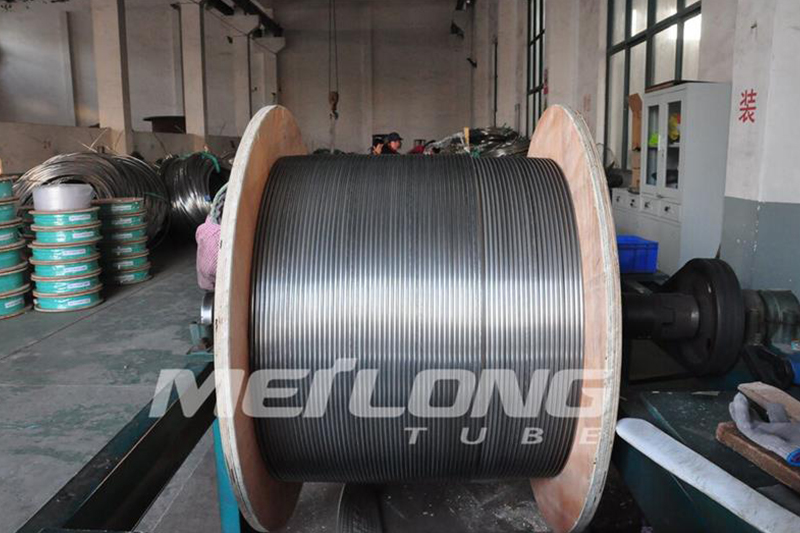

Product Display

Alloy Features

SS316L is an austenitic chromium-nickel stainless steel with molybdenum and a low carbon content.

Application

TP316L is used for a wide range of industrial applications where steels of type TP304 and TP304L have insufficient corrosion resistance. Typical examples are: heat exchangers, condensers, pipelines, cooling and heating coils in the chemical, petrochemical, pulp and paper and food industries.

Chemical Composition

|

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Nickel |

Chromium |

Molybdenum |

|

% |

% |

% |

% |

% |

% |

% |

% |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

|

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

10.0-15.0 |

16.0-18.0 |

2.00-3.00 |

|

Norm Equivalence |

||||

|

Grade |

UNS No |

Euro norm |

Japanese |

|

|

No |

Name |

JIS |

||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 | JIS G3463 |

| 316L | S31603 | 1.4404, 1.4435 | X2CrNiMo17-12-2 | SUS316LTB |

Technical Datasheet

|

Alloy |

O.D. |

W.T. |

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Working Pressure |

Burst Pressure |

Collapse Pressure |

|

inch |

inch |

Mpa |

Mpa |

% |

HV |

psi |

psi |

psi |

|

|

|

|

min. |

min. |

min. |

max. |

min. |

min. |

min. |

|

|

SS316L |

0.375 |

0.035 |

172 |

483 |

35 |

190 |

3,818 |

17,161 |

5,082 |

|

SS316L |

0.375 |

0.049 |

172 |

483 |

35 |

190 |

5,483 |

24,628 |

6,787 |

|

SS316L |

0.375 |

0.065 |

172 |

483 |

35 |

190 |

7,517 |

33,764 |

8,580 |

|

SS316L |

0.375 |

0.083 |

172 |

483 |

35 |

190 |

9,749 |

43,777 |

10,357 |

Product detail pictures:

Related Product Guide:

While using the "Client-Oriented" company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for Excellent quality Chemical Injection Line Tube - Capillary Tube Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Palestine, Sheffield, India, Upon today, we've customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We've been looking forward to doing business with you.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.