Europe style for S32750 Chemical Injection Line - Monel 400 Chemical Injection Line – MEILONG

Europe style for S32750 Chemical Injection Line - Monel 400 Chemical Injection Line – MEILONG Detail:

Product Introduction

One of the main challenges in the upstream processes of the oil and gas industry is to protect pipeline and process equipment against waxes, scaling and asphalthane deposits. The engineering disciplines involved in flow assurance play an essential part in mapping the requirements that reduce or prevent loss of production due to pipeline or process equipment blockage. Coiled tubing from Meilong Tube is applied to umbilicals and chemical injection systems play an effective role in chemical storage and delivery at an optimizing flow assurance.

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction.

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

A small-diameter conduit that is run alongside production tubulars to enable injection of inhibitors or similar treatments during production. Conditions such as high hydrogen sulfide [H2S] concentrations or severe scale deposition can be counteracted by injection of treatment chemicals and inhibitors during production.

To assure produced fluid flow and protect your production infrastructure from plugging and corrosion, you need reliable injection lines for your production chemical treatments. Chemical injection lines from Meilong Tube help enhance the efficiency of your production equipment and lines, both downhole and at surface.

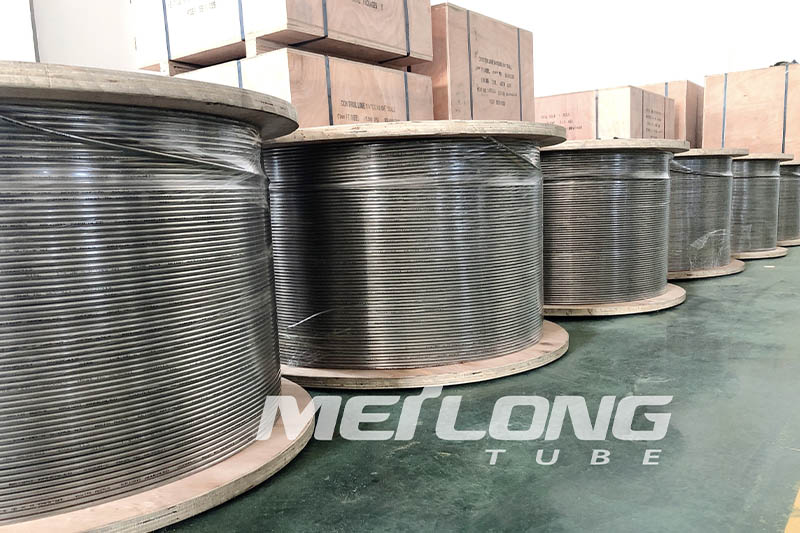

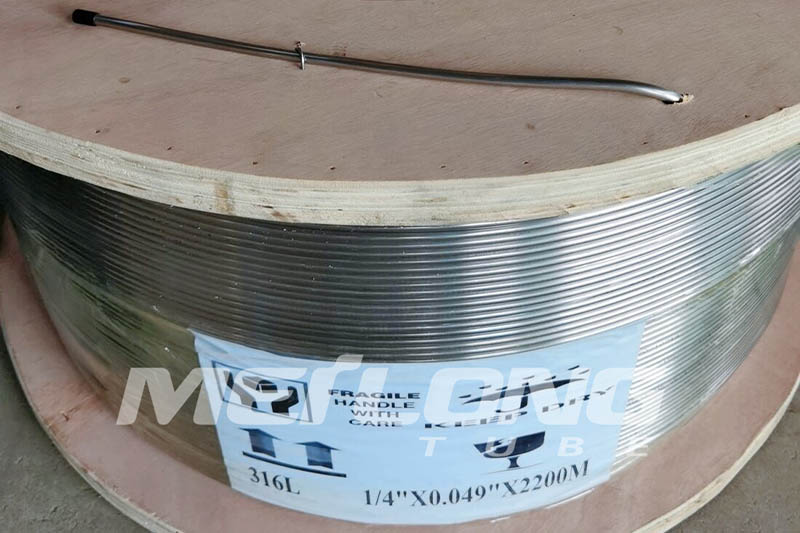

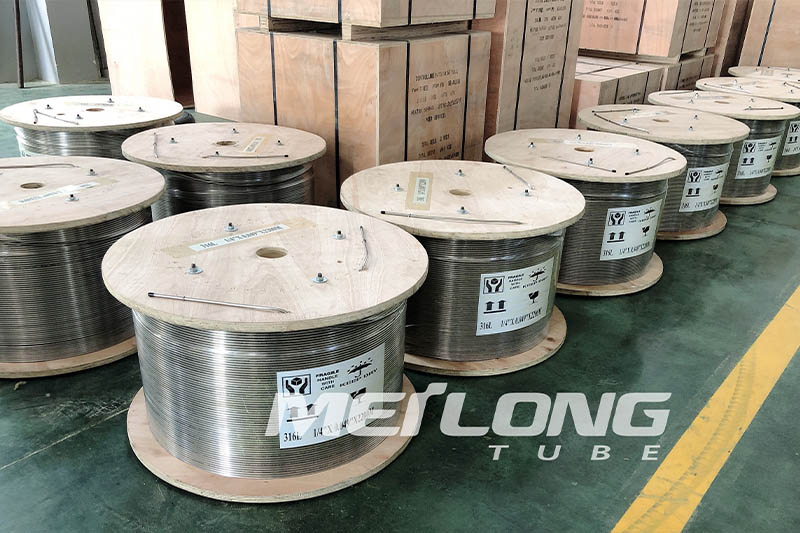

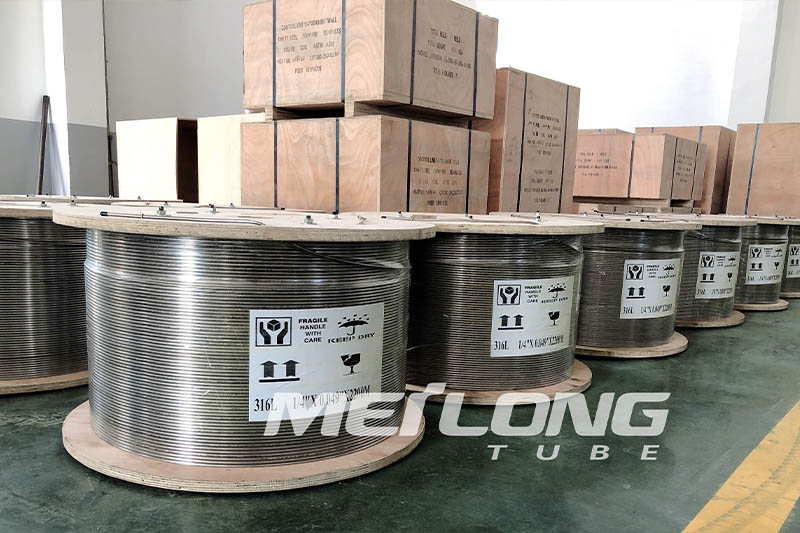

Product Display

Testing Abilities

| Chemical | Flare | Metallurgical |

| Corrosion | Flatten | Positive material identification (PMI) |

| Dimensional | Grain size | Surface roughness |

| Eddy current | Hardness | Tensile |

| Elongation | Hydrostatic | Yield |

Chemical Composition

|

Nickel |

Copper |

Iron |

Manganese |

Carbon |

Silicon |

Sulfur |

|

% |

% |

% |

% |

% |

% |

% |

|

min. |

|

max. |

max. |

max. |

max. |

max. |

|

63.0 |

28.0-34.0 |

2.5 |

2.0 |

0.3 |

0.5 |

0.024 |

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of Europe style for S32750 Chemical Injection Line - Monel 400 Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: luzern, Mauritius, Chile, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.