China Manufacturer for Incoloy 825 Capillary String - Santoprene TPV Encapsulated 316L Chemical Injection Line Tube – MEILONG

China Manufacturer for Incoloy 825 Capillary String - Santoprene TPV Encapsulated 316L Chemical Injection Line Tube – MEILONG Detail:

Product Introduction

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

The length without orbital welds which reduces the potential for defects and failures. Additionally, our coils have an extremely clean and smooth inside surface that is ideal for chemical injection systems. The coils offer short hydraulic response time, greater collapse strength, and elimination of methanol permeation.

Chemical injection lines from Meilong Tube help enhance the efficiency of your production equipment and lines, both downhole and at surface.

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction, geothermal power generation.

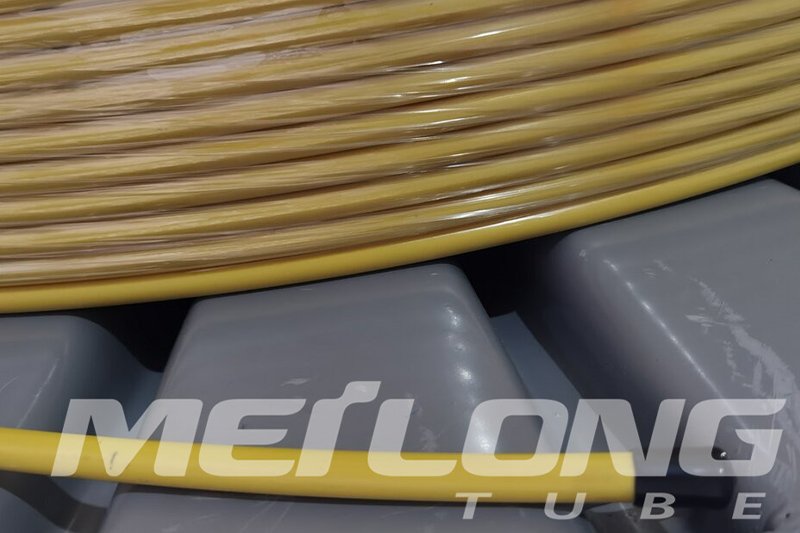

Product Display

Alloy Feature

Application

TP316L is used for a wide range of industrial applications where steels of type TP304 and TP304L have insufficient corrosion resistance. Typical examples are: heat exchangers, condensers, pipelines, cooling and heating coils in the chemical, petrochemical, pulp and paper and food industries.

Corrosion Resistance

Organic acids at high concentrations and moderate temperatures

Inorganic acids, e.g. phosphoric and sulphuric acids, at moderate concentrations and temperatures. The steel can also be used in sulphuric acid of concentrations above 90% at low temperature.

Salt solutions, e.g. sulphates, sulphides and sulphites

Chemical Composition

|

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Nickel |

Chromium |

Molybdenum |

|

% |

% |

% |

% |

% |

% |

% |

% |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

|

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

10.0-15.0 |

16.0-18.0 |

2.00-3.00 |

|

Norm Equivalence |

||||

|

Grade |

UNS No |

Euro norm |

Japanese |

|

|

No |

Name |

JIS |

||

|

Alloy |

ASTM/ASME |

EN10216-5 |

EN10216-5 |

JIS G3463 |

|

316L |

S31603 |

1.4404, 1.4435 |

X2CrNiMo17-12-2 |

SUS316LTB |

Product detail pictures:

Related Product Guide:

To get the stage of realizing dreams of our employees! To build a happier, more united and much more skilled crew! To reach a mutual benefit of our prospects, suppliers, the society and ourselves for China Manufacturer for Incoloy 825 Capillary String - Santoprene TPV Encapsulated 316L Chemical Injection Line Tube – MEILONG , The product will supply to all over the world, such as: Southampton, Luxemburg, Liverpool, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!