China Cheap price Inconel 625 Capillary Tube - FEP Encapsulated 316L Chemical Injection Line Tube – MEILONG

China Cheap price Inconel 625 Capillary Tube - FEP Encapsulated 316L Chemical Injection Line Tube – MEILONG Detail:

Tubing Features

Close dimensional tolerances

Considerably enhanced mechanical properties

Superior surface finish

High cleanness of inside surface

Controlled ovality, eccentricity

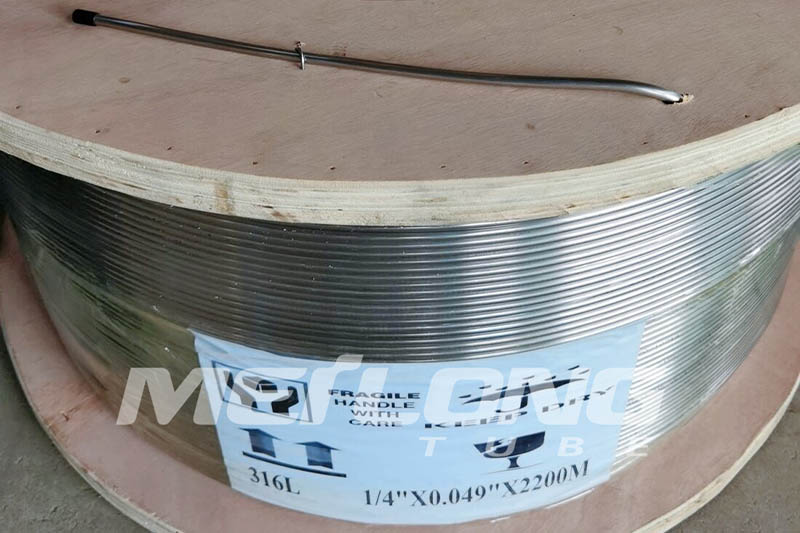

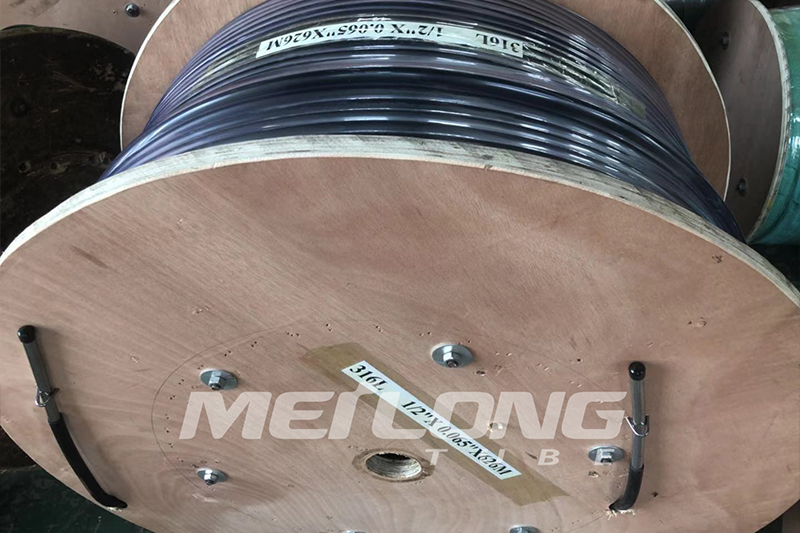

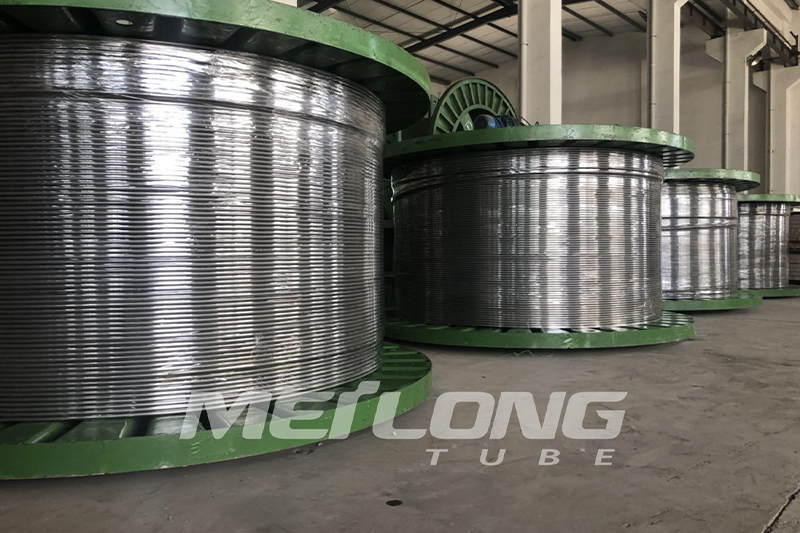

Product Display

Profile Of Single Line Encapsulation

| Round Profiles of Single Line Encapsulation | |

| 1/4’’ OD line tubing | 0.433’’ Dia (11.0 mm) |

| 3/8’’ OD line tubing | 0.535’’ Dia (13.6 mm) |

| 1/2’’ OD line tubing | 0.660’’ Dia (16.8 mm) |

| Square Profiles of Single Line Encapsulation | |

| 1/4’’ OD line tubing | 0.433’’ x 0.433’’ (11.0 mm x 11.0 mm) |

| 3/8’’ OD line tubing | 0.535’’ x 0.535’’ (13.6 mm x 13.6 mm) |

| 1/2’’ OD line tubing | 0.660’’ x 0.660’’ (16.8 mm x 16.8 mm) |

Alloy Feature

SS316L is an austenitic chromium-nickel stainless steel with molybdenum and a low carbon content.

Application

TP316L is used for a wide range of industrial applications where steels of type TP304 and TP304L have insufficient corrosion resistance. Typical examples are: heat exchangers, condensers, pipelines, cooling and heating coils in the chemical, petrochemical, pulp and paper and food industries.

Chemical Composition

|

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Nickel |

Chromium |

Molybdenum |

|

% |

% |

% |

% |

% |

% |

% |

% |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

|

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

10.0-15.0 |

16.0-18.0 |

2.00-3.00 |

|

Norm Equivalence |

||||

|

Grade |

UNS No |

Euro norm |

Japanese |

|

|

No |

Name |

JIS |

||

|

Alloy |

ASTM/ASME |

EN10216-5 |

EN10216-5 |

JIS G3463 |

|

316L |

S31603 |

1.4404, 1.4435 |

X2CrNiMo17-12-2 |

SUS316LTB |

Dimensional Tolerance

| ASTM A269 / ASME SA269, 316L, UNS S31603 | ||

| Size OD | Tolerance OD | Tolerance WT |

| ≤1/2’’ (≤12.7 mm) | ±0.005’’ (±0.13 mm) | ±15% |

| 1/2’’<OD≤1’’ (12.7<OD≤25.4 mm) | ±0.005’’ (±0.13 mm) | ±10% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| ≤1/2’’ (≤12.7 mm) | ±0.004’’ (±0.10 mm) | ±10% |

| 1/2’’<OD≤1’’ (12.7<OD≤25.4 mm) | ±0.004’’ (±0.10 mm) | ±8% |

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for China Cheap price Inconel 625 Capillary Tube - FEP Encapsulated 316L Chemical Injection Line Tube – MEILONG , The product will supply to all over the world, such as: Germany, Houston, Belgium, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!