Best Price for Super Duplex 2507 Chemical Injection Line Tube - Incoloy 825 Chemical Injection Line – MEILONG

Best Price for Super Duplex 2507 Chemical Injection Line Tube - Incoloy 825 Chemical Injection Line – MEILONG Detail:

Application

In all fields of the oil and gas industry, chemicals are injected into process lines and fluids. Take oilfield services, chemicals are used to film the side of the wellbore for improved stability. In pipelines they avoid build-up and keep the infrastructure healthy.

Other Application:

In the oil and gas industry we inject chemicals in order.

To protect the infrastructure.

To optimize processes.

To assure flow.

And to improve productivity.

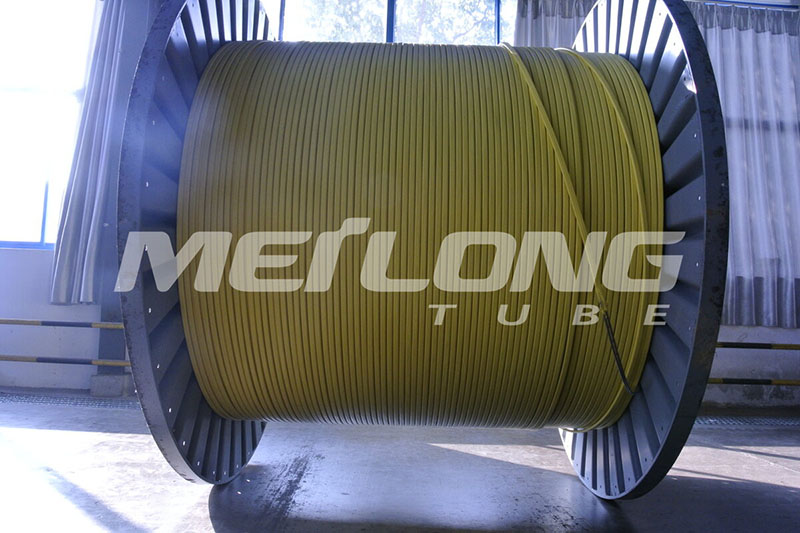

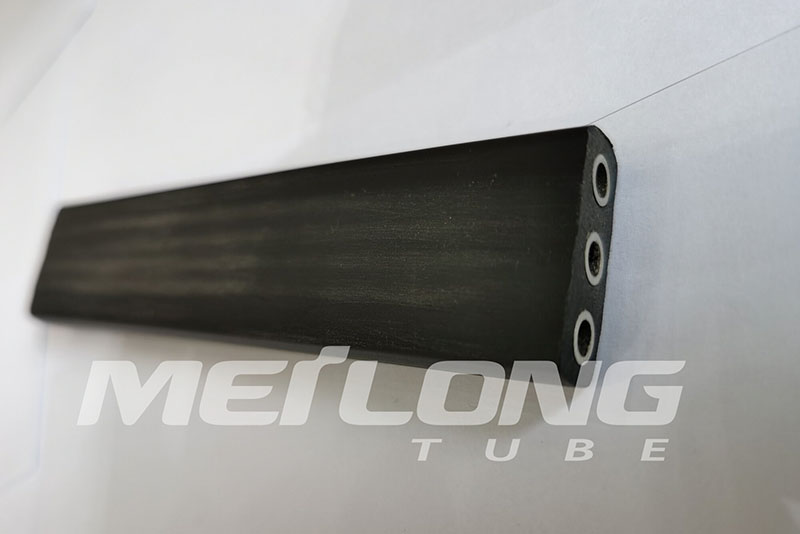

Product Display

Alloy Feature

Incoloy alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum and copper. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Tubing Process and Packing

Seamless: pierced, redrawn, annealed (multi-pass circulation process).

Welded: longitudinally welded, redrawn, annealed (multi-pass circulation process).

Packing: Tubing is level wound coiled on the metal / wooden drums or spools.

All drums or spools are packed in wooden crates for easy logistic operation.

Chemical Composition

|

Nickel |

Chromium |

Iron |

Molybdenum |

Carbon |

Manganese |

Silicon |

Sulfur |

Aluminum |

Titanium |

Copper |

|

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

|

|

|

min. |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

38.0-46.0 |

19.5-23.5 |

22.0 |

2.5-3.5 |

0.05 |

1.0 |

0.5 |

0.03 |

0.2 |

0.6-1.2 |

1.5-3.0 |

| Norm Equivalence | |||

|

Grade |

UNS No |

Euro norm |

|

|

No |

Name |

||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 |

| 825 | N08825 | 2.4858 | NiCr21Mo |

Product detail pictures:

Related Product Guide:

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Best Price for Super Duplex 2507 Chemical Injection Line Tube - Incoloy 825 Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Oslo, Venezuela, Istanbul, For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.